| Máy nạp rom, Jig test |

| » | Máy nạp rom đa năng |

| » | Máy nạp Gang đa năng |

| » | Máy nạp rom on-board |

| » | Máy nạp chuyên biệt |

| » | Hệ thống nạp tự động |

| » | Phụ kiện đế nạp socket |

| » | Xoá Rom, kiểm tra IC |

| » | Sao chép ổ cứng, thẻ nhớ |

| » | Jig test ICT/FCT/DIP-pallet |

| Đo lường và kiểm tra |

| » | Dao động ký oscilloscope |

| » | Thiết bị viễn thông, RF |

| » | Bộ thu thập dữ liệu |

| » | Đồng hồ vạn năng số |

| » | Máy phát xung, đếm tần |

| » | Máy đo LCR, linh kiện |

| » | Bộ đổi nguồn, tải điện tử |

| » | Kit đào tạo, thực hành |

| Các công cụ sản xuất |

| » | Máy khò, mỏ hàn thiếc |

| » | Tủ sấy, tủ môi trường |

| » | Dây chuyền SMT Line |

| » | Thiết bị sản xuất PCBA |

| Thiết bị, công cụ khác |

| » | Thiết bị Automotive |

| » | Đo lực, cơ điện khác |

| » | Thiết bị quang học |

| Linh phụ kiện Điện tử |

| » | Vi điều khiển họ 8051 |

| » | Nuvoton ARM Cortex-M |

| » | Nuvoton ARM7/9 Soc |

| » | Chip phát nhạc, audio |

| » | Wireless RF IC, Tools |

| » | Vật tư hàn, rửa mạch |

| e-Shop thiết bị, vật tư |

|

|

|

Hiện tại có 0 khách và 0 thành viên đang online.

Bạn là khách. Bạn có thể đăng kí bằng cách nhấn vào đây |

OUR PARTNERS

(Products Line-Card)

|

| |

Danh mục nội dung: Chuyên mục chính/3. Hệ thống, công cụ và thiết bị phát triển sản xuất điện tử/3.4. Hệ thống dây chuyền sản xuất SMT (SMT Line system)

| | | | | ◊ Đặc điểm chính: | | | - Tự động làm sạch , dễ học và vận hành ổn định . giải pháp tốt nhất cho quá trình in bán dẫn |

|

|

| | | | - Applied to diverse stencils

- Uncomplicated operations

- Easy to change the lines

- High printing precision

- Áp dụng cho các loại giấy nến

- Các hoạt động đơn giản

- Dễ dàng thay đổi dòng

- Độ chính xác in cao

| - Auto stencil cleaning: Standard Specification, including Wet wiping, dry wiping and Exhausting the air.

- Humanity software: Easy to learn and operate.

- When Blade is working under stencil or departing from stencil; it will not move up and down; to ensure the steady of printing.

- Blade tooling with floating blade and device of constant pressure, it will not influence the quality when changing the blade.

- Built-in multistage function for separated board could prevent the solder stain the boards.

- Z axis print platform working fast and steady, could increase the printing flatness of increase the printing flatness of pc board.

- The vacuum device is option, for under 0.6mm board.

- Alignment system with the multi binary control, and include the X,Y,θ high precision movement, ensure the printing fixed accuracy.

- Tự động làm sạch stencil: Thông số kỹ thuật tiêu chuẩn, bao gồm Lau ướt, lau khô và Xả không khí.

- Phần mềm nhân văn: Dễ học và vận hành.

- Khi Blade đang làm việc dưới stencil hoặc khởi động từ stencil; nó sẽ không di chuyển lên và xuống; để đảm bảo việc in ấn ổn định.

- Dụng cụ lưỡi có lưỡi nổi và thiết bị chịu áp lực không đổi nên sẽ không ảnh hưởng đến chất lượng khi thay lưỡi.

- Chức năng đa tầng tích hợp cho bo mạch riêng biệt có thể ngăn chất hàn làm bẩn bảng.

- Nền tảng in trục Z hoạt động nhanh và ổn định, có thể tăng độ phẳng in và tăng độ phẳng in của bảng máy tính.

- Thiết bị chân không là tùy chọn, cho bảng dưới 0,6mm.

- Hệ thống căn chỉnh với điều khiển đa nhị phân, và bao gồm chuyển động chính xác cao X, Y, θ, đảm bảo độ chính xác cố định của việc in.

| 【Function】 Stencil plate arm adopts high-accuracy square rail to make horizontal sliding, it is smooth going and suits for various stencil.

Humanization controls interface; easy to operate.

Platform has no interval to finely adjustment, with changes the line not only correctly but also fast.

The distance is adjusted to print between the stencils; it offers merely short time adjustment and high accuracy by percentage form make for moving from basis.

Print the integrative shaping of the complexion of seats, have long life spin; won't be in fluenced

【Chức năng】

Áp dụng cho các loại giấy nến Cánh tay tấm stencil sử dụng đường ray vuông có độ chính xác cao để trượt ngang, nó hoạt động trơn tru và phù hợp với nhiều loại giấy nến khác nhau. - Các hoạt động không phức tạp

Giao diện điều khiển nhân hóa; dễ dàng hoạt động. - Nền tảng không có khoảng thời gian để điều chỉnh tinh vi, với những thay đổi dòng không chỉ chính xác mà còn nhanh chóng.

- Khoảng cách được điều chỉnh để in giữa các giấy nến; nó chỉ cung cấp điều chỉnh trong thời gian ngắn và độ chính xác cao theo tỷ lệ phần trăm giúp cho việc di chuyển từ cơ sở.

In hình tích hợp của da ghế, có vòng quay tuổi thọ cao; sẽ không thành thạo.

| 【Application】

Apply to SMT/Semiconductor Stencil/ Screen printing, also for the solder paste printing/ glue printing process. Best solution for semiconductor printing process. Repeat printing could achieve to ±10μm. (For 01005 component requirement.) Low cost fully auto printer, outstanding & high performance printer in this fields. Equipped best resolution CCD vision alignment system.

【Ứng dụng】 - Áp dụng cho SMT / Stencil bán dẫn / In lụa, cũng cho quá trình in / in keo hàn.

- Giải pháp tốt nhất cho quá trình in bán dẫn.

- In lặp lại có thể đạt đến ± 10μm. (Đối với yêu cầu thành phần 01005.)

- Máy in hoàn toàn tự động chi phí thấp, máy in hiệu suất cao và vượt trội trong các lĩnh vực này.

- Được trang bị hệ thống căn chỉnh tầm nhìn CCD độ phân giải tốt nhất.

【Operational Vision】 - Diagrammatic window operating page.

- Human Operational Environment.

- Easy to learn and operate.

【Tầm nhìn hoạt động】 - Trang điều hành cửa sổ dạng sơ đồ.

- Môi trường hoạt động của con người.

- Dễ học và vận hành.

|  |

【System Setting】

- Provide alignment diagrammatic machine.

- Windows Operational Is Easy to learn and operate.

Thiết lập hệ thống】 - Cung cấp máy sơ đồ căn chỉnh.

- Hoạt động của Windows rất dễ học và vận hành.

|  |

【Printing Mechanism】 - Floating blade and constant pressure system : Control the printing pressure accuracy on each position.

- Built-in multistage function for separated board could prevent the solder stain the board.

- Blade is working under stencil or departing from stencil; it will not move up and down; to ensure the steady printing.

【Cơ chế in】 - Lưỡi dao nổi và hệ thống áp suất không đổi: Kiểm soát độ chính xác của áp suất in trên từng vị trí.

- Chức năng đa tầng tích hợp cho bo mạch riêng biệt có thể ngăn vết hàn làm bẩn bảng.

- Blade đang hoạt động dưới stencil hoặc khởi động từ stencil; nó sẽ không di chuyển lên và xuống; để đảm bảo in ổn định.

|  |

| 【Applied industry】 1.Applied for SMT, PCB, LCD, IC packaging and semiconductor industries...etc.

2.Custom-made products are available (for special specifications of other industries).

【Custom-made products】 1.Jig, Two-sided jig.

2.Steel scraper.

【Ngành ứng dụng】 1. áp dụng cho SMT, PCB, LCD, đóng gói vi mạch và các ngành công nghiệp bán dẫn ... vv. 2. Sản phẩm tùy chỉnh có sẵn (cho các thông số kỹ thuật đặc biệt của các ngành công nghiệp khác). 【Sản phẩm làm theo yêu cầu】 1.Jig, Đồ gá hai mặt. 2. Cạp thép. 【Tiêu hao】 Thép cạp. | 【Clean device】 - Auto stencil cleaning : Standard equipment, including Wet wiping 、Dry wiping and Exhausting the air.

- To ensure the smooth and reliable operation, the auto. steel-wire clean system and CCD device are separated.

- To ensure the printing and cleaning quality, all parameters can be set such as clean mode and clean cycle etc.

- Extra function to strengthen the clean.

【Làm sạch thiết bị】 - Tự động làm sạch giấy nến: Thiết bị tiêu chuẩn, bao gồm Lau ướt 、 Lau khô và Xả khí.

- Để đảm bảo hoạt động trơn tru và đáng tin cậy, tự động. Hệ thống sạch bằng dây thép và thiết bị CCD được tách biệt.

- Để đảm bảo chất lượng in và làm sạch, tất cả các thông số có thể được thiết lập như chế độ sạch và chu trình sạch, v.v.

- Chức năng bổ sung để tăng cường sự sạch sẽ.

|  |

【Clean device】 - CCD vision alignment module : multi binary control.

- The vacuum device is option, for under 0.6mm board.

- Programmable and adjustable high-speed PCB transmission system.

- On-axis light and ring lamp to be used, could check for different types of PCB board.

【Làm sạch thiết bị】 - Mô-đun điều chỉnh tầm nhìn CCD: điều khiển đa nhị phân.

- Thiết bị chân không là tùy chọn, cho bảng dưới 0,6mm.

- Hệ thống truyền dẫn PCB tốc độ cao có thể lập trình và điều chỉnh.

- Đèn trên trục và đèn vòng được sử dụng, có thể kiểm tra các loại bảng mạch PCB khác nhau.

|  |

【Pressplate/backup plate】 - Precise clamping system can effectively overcome the printing accuracy for curved PCB.

- Suitable for most single-side/duplicated and multi-layer PCB board.

【Tấm ép / tấm dự phòng】 - Hệ thống kẹp chính xác có thể khắc phục hiệu quả độ chính xác in cho PCB cong.

- Thích hợp cho hầu hết các bảng mạch PCB một mặt / nhân đôi và nhiều lớp.

|  |

|

【Specifications】

Mainframe of Machinery

| Specifications | KP100 | KP100L | KP100XL | | Dimension | 750mm*900mm*1450mm | 1000mm*970mm*1500mm | 1600mm*825mm*1500mm | | Weight | About 250Kg | 300Kg | 350Kg

| | Electric power supply | 1kw,4A | | Voltage | AC 1Ø,220V,50/60HZ | | Air Supply | Clean dry air 5~6kg/cm2 30 l/min |

Print specification

| Specifications | KP100 | KP100L | KP100XL | | Applied thickness of baseboard | 0.5~5mm | | Platform area | 400mm*300mm | 600mm*500mm | 1250mm*350mm | | Print area | 350mm*250mm | 550mm*450mm | 1200mm*300mm | | Print speed | 5~250mm/sec | | Print direction | Left to right/Right to left print | | Print pressure are | 0.5~5kg/cm2 | | Working platform height | 900mm | | Stencil (net) board dimension (max) | 735mm*550mm | 1000mm*735mm | 1600mm*550mm | | Fine tuning | Pin | | Fixed position | X:±10mm Y:±10mm | | Print precision | ±20μm | ±20μm | ±30μm |

| 【Specifications】

Machine Information

| | KP510A | | Approx dimension | 1110mm*1390mm*1561mm | | Approx weight | Approx. 950Kg | | Power supply | AC 1Ø,220V,50/60HZ;2kw,10A | | Air supply | Clean dry air 5~6kg/cm2 30L/min | | Operation interface | Windows interface |

Board Specification

| | KP510A | | Suitable dimension of board | max:400*310(mm) min:50*50(mm) | | Suitable thickness of board | 0.6~6(mm) | | Board width adjustment | Auto | | Suitable weights of board | 3kg or less | | Board clamping tooling | Edge clamp (Could adjust the softness) |

Print Parameters

| | KP510A | | Stencil frames | max:735*735(mm) min:650*550(mm) | | Print area | max:400*310(mm) min:50*50(mm) | | Print pressure | 0~5kg/cm2 | | Stencil separation speed | 0.1~5mm/sec (Programmable) | | Print direction | Front to back/Back to front | | Print speed | 5~250mm/sec |

Vision System

| | KP510A | | CCD camera | High resolution CCD | | Image process | Multi binary control | | Fiducials | 2 | | Fiducial spec | 0.1mm~3.0mm | | Fiducial position | Any point on PCB | | Fiducial error recovery | Auto fiducial search |

Machine Capability

| | KP510A | | Repeat Precision | ±10μm | | Printing precision | ±20μm | | Cycle Time | <7.5sec | | Clean function | Wet wiping/Dry wiping/Exhaust the air | | Clean dimension | X:400mm |

Option

|  | Thimble/ejector bar

| Vacuum holding fixture module

|

|

【Download】

| | | Catalogue |  KP510A.pdf KP510A.pdf | | | | Video |  KP510A.mpg KP510A.mpg | | | | Manual |  KP510A.pdf KP510A.pdf |

CÁC SẢN PHẨM KHÁC CÙNG NHÀ SẢN XUẤT / OTHER PRODUCTS FROM GENITEC |

|

|

| | |

ĐỐI TÁC QUỐC TẾ

Minato, Leap, SMH-Tech, Xeltek, Elnec, Conitec, DediProg, Phyton, Hilosystems, Flash Support Group, PEmicro || Rigol, Tonghui, Copper Mountain, Transcom, APM || Atten, Zhuomao, Puhui, Neoden, Ren Thang, Genitec, Edry, UDK ||

|

ENGLISH

ENGLISH Trang chủ

Trang chủ

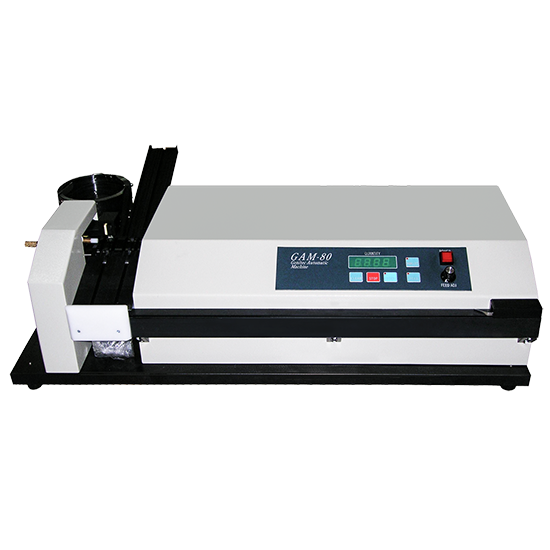

KP series: Printer-Expert in printing process (Máy in kem hàn tự động)

KP series: Printer-Expert in printing process (Máy in kem hàn tự động)