Danh mục nội dung: Chuyên mục chính/3. Hệ thống, công cụ và thiết bị phát triển sản xuất điện tử/3.3. Công cụ hàn thiếc, khò IC và gia công PCB lô nhỏ (Soldering tools, rework system)

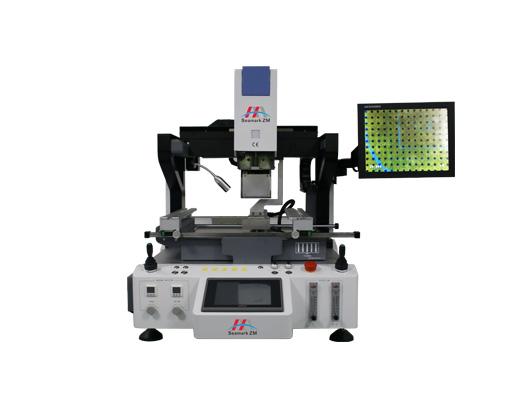

| | | | | ◊ Đặc điểm chính: | | All Mobile Phone Board, LED ( LED lamp ), IC, AMD, CPU, Laptop, PS3,PS4,XBOX360 TV motherboard, TV set top box ( Multi-Media and set top box ), Computer PC Defence and Aerospace, Gaming Console, Storage, etc. - 3 independent control heaters

- adopt Panasonic automatic Vision Alignment System

- With optical grating protection, when the machine is working, if the optical grating signal was blocked, then the machine will stop operation immediately

- With computer operation, high accuracy K type close-loop thermocouple, and PID parameters automatic adjustment system

- Stable and Uniform Hot Air Heating System

- Lower Heater Adjustable

- Extreme Large Carbon Fiber Infrared Pre-heater

- High-Precision PID Temperature Control System

- Industrial High-Definition CCD (2 x 5.0 MP)

- PC Control Automatic Image Recognition System

- Full Automatic Placement, Desoldering

- Built-In Pressure Testing Device To Protects The PCB

- Real-Time Temperature Monitoring and Over-Temperature Protection.

- Emergency Stop Function

- SMD Feeding Device Support (Optional)

Máy này sử dụng máy tính điều khiển công nghiệp, hệ thống căn chỉnh tầm nhìn hoàn toàn tự động có thể thu nhận BGA và hình ảnh PCB thông qua camera CCD và thu thập chúng trên hệ thống xử lý định vị hình ảnh, tính toán vị trí và góc lệch thông qua phần mềm xử lý hình ảnh, sau đó truyền lại đến ổ đĩa động cơ của bộ điều khiển servo để điều chỉnh vị trí, do đó hoàn thành vị trí BGA. Phản hồi nhanh, độ chính xác định vị lên đến ± 0,005 MM, với bàn phím, chuột và màn hình LCD HD 15 inch. |

|

|

Tính năng- 3 lò sưởi điều khiển độc lập

- áp dụng Hệ thống căn chỉnh tầm nhìn tự động của Panasonic

- Với tính năng bảo vệ cách tử quang học, khi máy đang làm việc, nếu tín hiệu lưới quang bị chặn thì máy sẽ ngừng hoạt động ngay lập tức

- Với hoạt động của máy tính, cặp nhiệt điện vòng kín loại K có độ chính xác cao và hệ thống điều chỉnh tự động các thông số PID

- Hệ thống sưởi không khí nóng ổn định và thống nhất

- Máy sưởi thấp hơn có thể điều chỉnh

- Bộ gia nhiệt sơ bộ hồng ngoại sợi carbon cực lớn

- Hệ thống kiểm soát nhiệt độ PID chính xác cao

- CCD độ nét cao công nghiệp (2 x 5,0 MP)

- Hệ thống nhận dạng hình ảnh tự động điều khiển PC

- Vị trí hoàn toàn tự động, khử mùi

- Thiết bị kiểm tra áp suất tích hợp để bảo vệ PCB

- Theo dõi nhiệt độ thời gian thực và bảo vệ quá nhiệt.

- Chức năng dừng khẩn cấp

- Hỗ trợ thiết bị cho ăn SMD (Tùy chọn)

Ứng dụng- SMT

- Semiconductor industry

- Maintenance of individual

- Computer graphics

- Mobile phone repair shop

- Digital cameras Projectors

- Game consoles

- Audio

- After sales Service

1, Máy này sử dụng điều khiển máy tính công nghiệp, hệ thống căn chỉnh tầm nhìn tự động hoàn toàn có thể thu nhận BGA và hình ảnh PCB thông qua camera CCD và thu thập chúng trên hệ thống xử lý định vị hình ảnh, tính toán vị trí và góc lệch thông qua phần mềm xử lý hình ảnh, sau đó truyền lại đến ổ đĩa động cơ của bộ điều khiển servo để điều chỉnh vị trí, do đó hoàn thành vị trí BGA. Phản hồi nhanh, độ chính xác định vị lên đến ± 0,005 MM, với bàn phím, chuột và màn hình LCD HD 15 inch. 2, Trong quá trình gắn, máy có thể tự động phân tích, tìm kiếm, sửa đổi vị trí của BGA hoặc PCB, và thông qua vòi phun để tự động nhận BGA và gắn nó vào miếng đệm được chỉ định, Khi giải nhiệt, nó có thể tự động loại bỏ BGA trên PCB và đặt nó vào vị trí được chỉ định. 3, Lò sưởi phía trên có thể được di chuyển tự do, hệ thống X, trục Y và góc R được sử dụng hệ thống điều khiển servo Panasonic, căn chỉnh quang học, có thể xoay 360 độ, tự động định vị, hệ thống sửa lỗi tự động, để mã PIN bật BGA và PCB pad hoàn toàn phù hợp. 4, Tốc độ lắp có thể được kiểm soát theo yêu cầu công việc. 5, Đầu làm nóng đỉnh và đầu gắn thiết kế độc lập ngăn bút hút không bị biến dạng bởi không khí nóng. Các chuyển động của trục Z được điều khiển bởi hệ thống servo Panasonic có thể điều khiển chính xác vị trí và các điểm thăm dò, kích thước khác nhau của đầu phun BGA, xoay 360 độ, dễ dàng lắp đặt và thay thế. Tùy chỉnh có sẵn. 6, Có 3 lò sưởi độc lập. Máy sưởi không khí nóng thứ nhất và thứ hai có thể kiểm soát nhiều nhóm và phân đoạn thông số nhiệt độ. Bộ gia nhiệt IR diện tích lớn thứ 3 có thể làm nóng hoàn toàn bảng mạch PCB để đảm bảo bo mạch không bị biến dạng. Nhiệt độ, thời gian, độ dốc, làm mát, báo động tất cả đều có thể hiển thị trên màn hình cảm ứng. 7, Cặp nhiệt điện kiểu K có độ chính xác cao với điều khiển vòng kín, hệ thống nhiệt độ hệ thống tự động điều chỉnh PID, kết hợp với PLC Panasonic và mô-đun nhiệt độ có độ nhạy cao để kiểm soát nhiệt độ chính xác, sai số nhiệt độ được kiểm soát trong phạm vi ± 1 độ, 5 cảm biến bên ngoài có thể phát hiện nhiệt độ chính xác, phân tích và hiệu chỉnh đường cong nhiệt độ thực một cách chính xác. 8, Hỗ trợ PCB rãnh chữ V, định vị nhanh chóng, tiện lợi, chính xác, có thể phù hợp với tất cả các loại bảng PCB. 9, Vật cố định đa năng linh hoạt và có thể tháo rời có tác dụng bảo vệ và không làm hỏng bo mạch PCB, thích hợp cho tất cả các loại sửa chữa BGA. 10, Quá trình lắp, hàn và khử ẩm được điều khiển thông minh và hoạt động tự động, vị trí lắp BGA được kiểm soát chính xác, sau khi khử hàn và hàn, có báo động. Khi nhiệt độ vượt quá tầm kiểm soát, mạch sẽ tự động ngắt nguồn. 11, Nó có thể lưu bộ nhớ 1000 bộ thông số nhiệt độ của các điểm và vị trí định vị chip BGA. Có thể phân tích và sửa đổi các thông số nhiệt độ trên màn hình cảm ứng bất cứ lúc nào, hiển thị và lưu trữ 8 đường cong nhiệt độ và nhiều bộ dữ liệu người dùng. Nó có thể phân tích đường cong chuyển động ngay lập tức. 12, Quạt thông gió mạnh mẽ để làm mát PCB tự động sau khi khử hàn và hàn, nó ngăn chặn sự biến dạng của bảng PCB để đảm bảo hiệu quả hàn. 13, Khí thải sinh ra trong quá trình hàn có thể tự động thải ra ngoài, để đảm bảo sức khỏe người vận hành và bảo vệ môi trường. 14, Được trang bị cảm biến áp suất và quang học để kiểm soát áp suất trong 3-10 gam và công tắc quang học, để nó có thể tự động nhận ra chip hút và chiều cao lắp, để đảm bảo không đè bẹp chip BGA, nó có thể sửa chữa Socket775 và gấp đôi BGA / CGA / IC và các thiết bị che chắn khác nhau, đáp ứng yêu cầu của quy trình không chì. 15, Máy hàn được trang bị bộ lọc tích hợp thông qua C.A.T phía nam của Công ty phát triển công nghệ bằng sáng chế, vật liệu lọc CACF than hoạt tính, có thể hấp thụ hiệu quả khói hàn, khí carbon dioxide và mùi hữu cơ, hiệu suất lọc khí đạt đến 99,7%. Buồng quạt kín được trang bị vật liệu hấp thụ âm thanh, Nó có thể đảm bảo rằng thiết bị hoạt động yên tĩnh. Nói một cách dễ hiểu, It’s cấu trúc nhỏ gọn, kích thước nhỏ, sử dụng thuận tiện. 16, Máy được trang bị camera giám sát quá trình, có thể quan sát rõ ràng quá trình công nghệ hàn bi trong khi gia nhiệt, đảm bảo hiệu quả hàn cao và đáng tin cậy.

THÔNG SỐ KỸ THUẬT/ SPECIFICATIONS

1 | Total Power | 9800W | 2 | Top heater | 1200W | 3 | Bottom heater | 2nd heater 1200W,3rd IR heater 7200W | 4 | power | AC220V±10% 50/60Hz | 5 | Dimensions | 1100*1300*1700mm(LCD stand not included) | 6 | Positioning | V-groove PCB support,and with external universal fixture | 7 | Temperature control | K-type thermocouple (Closed Loop), heating independently, temperature precision within ±1 degree | 8 | PCB size | Max 500*600mm Min 10*20 mm | 9 | Electrical materials | Servo Drive( Panasonic)+Industrial Host+ Heating plate(Germany) | 10 | Optical system | Servo Drive+ Automatic Vision Alignment System(Panasonic) | 11 | BGA chip | 2×2-80×80mm | 12 | External temperature sensor | five | 13 | Work Mode | Computer intelligence operations | 14 | Placement Accuracy | X, Y axis and the R angle with micrometer adjust, servo drive, accuracy within ±0.005MM | 15 | Net weight | 400kg |

CÁC SẢN PHẨM KHÁC CÙNG NHÀ SẢN XUẤT / OTHER PRODUCTS FROM Zhuomao |

|

ENGLISH

ENGLISH Trang chủ

Trang chủ

ZM-R8650 series: Trạm hàn chipset BGA tự động/ Fully Automatic BGA Rework Station

ZM-R8650 series: Trạm hàn chipset BGA tự động/ Fully Automatic BGA Rework Station