| Máy nạp rom, Jig test |

| » | Máy nạp rom đa năng |

| » | Máy nạp Gang đa năng |

| » | Máy nạp rom on-board |

| » | Máy nạp chuyên biệt |

| » | Hệ thống nạp tự động |

| » | Phụ kiện đế nạp socket |

| » | Xoá Rom, kiểm tra IC |

| » | Sao chép ổ cứng, thẻ nhớ |

| » | Jig test ICT/FCT/DIP-pallet |

| Đo lường và kiểm tra |

| » | Dao động ký oscilloscope |

| » | Thiết bị viễn thông, RF |

| » | Bộ thu thập dữ liệu |

| » | Đồng hồ vạn năng số |

| » | Máy phát xung, đếm tần |

| » | Máy đo LCR, linh kiện |

| » | Bộ đổi nguồn, tải điện tử |

| » | Kit đào tạo, thực hành |

| Các công cụ sản xuất |

| » | Máy khò, mỏ hàn thiếc |

| » | Tủ sấy, tủ môi trường |

| » | Dây chuyền SMT Line |

| » | Thiết bị sản xuất PCBA |

| Thiết bị, công cụ khác |

| » | Thiết bị Automotive |

| » | Đo lực, cơ điện khác |

| » | Thiết bị quang học |

| Linh phụ kiện Điện tử |

| » | Vi điều khiển họ 8051 |

| » | Nuvoton ARM Cortex-M |

| » | Nuvoton ARM7/9 Soc |

| » | Chip phát nhạc, audio |

| » | Wireless RF IC, Tools |

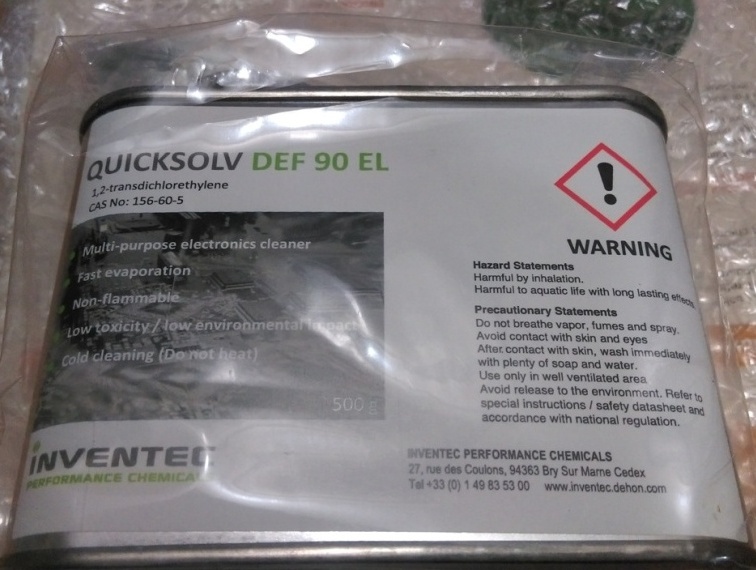

| » | Vật tư hàn, rửa mạch |

| e-Shop thiết bị, vật tư |

|

|

|

Hiện tại có 0 khách và 0 thành viên đang online.

Bạn là khách. Bạn có thể đăng kí bằng cách nhấn vào đây |

OUR PARTNERS

(Products Line-Card)

|

| |

Danh mục nội dung: Chuyên mục chính/5. Vật tư, hoá chất cho sửa chữa, gia công bảng mạch PCBA/5.1. Kem hàn và hàng liên quan (solder paste, related parts)

| | | | | ◊ Đặc điểm chính: | | HALOGEN FREE SOLDER PASTE - KEM HÀN KHÔNG CHỨA CHẤT ĐỘC HALOGEN

ROBUST ASSEMBLY - ĐÁP ỨNG NHU CẦU DÙNG CHO GIA CÔNG SẢN XUẤT QUY MÔ LỚN

ECORELTM FREE 305-16 is a no clean, lead-free solder paste developed with the reliable chemistry of the ECORELTM range:

- Very good wetting on any surface finish including OSP and strong anti-graping properties

- Robust assembly process for high volume electronics and complex boards

- Outstanding first pass yield testability in ICT

- Transparent and colorless residue even after multiple reflow cycles

- Stable performance up to 31 days when stored at room temperature (30°C max)

- Fine particle size distribution of type 4 powder enhances the printing quality.

Thực tế dùng Kem hàn Ecorel Free 305-16 T4 này thấy cho chất lượng cực tốt, độ ướt (wetting) cao nên kem hàn dẻo, tạo độ bám ngấu mối hàn rất tốt, hạn chế tối đa vệt - dây thiếc (graping) ở mối hàn hẹp (fine pitch) và cho số lỗ rỗng (void) rất ít, nhỏ. Vì vậy, kem hàn này đáp ứng cực tốt cho các nhu cầu sản xuất yêu cầu rất cao về chất lượng, hoặc những ứng dụng sản phẩm khá đặc biệt như hàng mạch LED, mạch Automotive, mạch Y tế hoặc hàng mạch Viễn thông, công nghiệp, Smart-phone...

|

|

|

Inventec has been developing, since more than 25 years, solder pastes which meet the production characteristics and reliability requests of its customers.

With its references in industrial High Tech markets, in the automotive, military, aeronautics fields, Inventec proposes a wide and complete range of ECORELTM and SOLDERELTM solder pastes with metallurgic, physical and chemical features.

Với bề dày hơn 25 năm phát triển sản phẩm kem hàn, các sản phẩm của Inventec đã đáp ứng các yêu cầu về độ tin cậy và đặc tính trong sản xuất quy mô công nghiệp.

Với các tài liệu tham khảo trong các thị trường công nghiệp Công nghệ Cao như xe cơ giới (automotive), quân sự (military) và hàng không (aeronautics), Inventec đề xuất một loạt các sản phẩm kem hàn ECORELTM và SOLDERELTM hoàn chỉnh về các tính năng lý, hoá và luyện kim.

ECORELTM solder pastes meet the increasing number of challenges in the electronics industry due to both the evolution of the technology itself, and new legislations. Halogen free, lead free, embedded technologies, hybrid assembly, miniaturization, and other requirements are covered.

- Chemical reliability of residues after reflow.

- Thermal cycling performance.

- Compatibility with Conformal Coating in No Clean process.

Alternative Alloys

No Clean Lead Free Solder Pastes

- Sensitive components soldering

- Improved drop shock performance

More than 2 decades of experience in high reliability markets such as automotive, energy and aerospace. For our customers, having the correct choice of materials certainly contributes to increase in long term performance and to drop in maintenance costs.

QUICK ECORELTM SOLDER PASTE SELECTION GUIDE

|

Product Name

|

Alloy

|

Main Features

|

Halogen Free

|

Bono Test

|

Squeegee printing

|

Closed Head Printing

|

Pin in Paste

|

Packaging

|

|

Jar

|

Cartridge

|

Syringe

|

|

250 g

500 g

|

600g

1,2 kg

|

30 g

|

100 g

|

|

EcorelTM Free 305-21

|

SAC305

|

Chemically inert residue, minimizing the risk of corrosion mechanisms and leakage current

Good compatibility with a large range of conformal coating in the market

Bono corrosion test compliant

|

√

|

√

|

√

|

√

|

√

|

√

|

√

|

|

|

|

EcorelTM Free 305-16 LVD

|

SAC305

|

Ultra low voiding percentage and reduce void size in large contact are components

|

√

|

|

√

|

√

|

√

|

√

|

√

|

|

|

|

EcorelTM Free 305-16

|

SAC305

|

Very good wetting on any surface finish

Strong anti-graping properties

Robust assembly process for high volume

Outstanding first pass yield testability

Very low voiding

Transparent and colorless residue even after multiple reflow cycles

|

√

|

|

√

|

√

|

√

|

√

|

√

|

|

|

|

EcorelTM Free 305-6D33

|

SAC305

|

Compatible with polyurethane and acrylic conformal coatings

Bono corrosion test compliant

Very low ionic contamination

|

√

|

√

|

√

|

√

|

|

√

|

√

|

|

|

|

EcorelTM Free 405Y-21

|

SAC405

+ dopants

|

High mechanical reliability for high operating temperatures

Thermal cycling resistance

Bono corrosion test compliant

|

√

|

√

|

√

|

√

|

√

|

√

|

√

|

|

|

|

EcorelTM Free 305-1-85

|

SAC305

|

Great repeatability dot by dot

|

√

|

|

|

|

|

|

|

√

|

√

|

|

EcorelTM Free HT245-16

|

SnSb8.5

|

Higher melting point than SAC alloy suitable for electronics operating close to 200°C, hybrid or stacking assembly including board on board

|

√

|

|

√

|

|

|

√

|

√

|

|

|

|

EcorelTM Free JP20

|

SAC305

|

Minimum dot diameter of 0.33 mm, T5 particle size

Large process window. Easy cleanable

Compatible with jet printer

|

√

|

|

|

|

|

|

|

|

√

|

|

EcorelTM Free FR2

|

SAC305

|

Reflow process by laser or induction

|

√

|

|

|

|

|

|

|

|

√

|

ALTERNATIVE ALLOYS SELECTION GUIDE

|

Product Name

|

Alloy

|

Main Features

|

Halogen Free

|

Bono Test

|

Squeegee printing

|

Dispensing

|

Pin in Paste

|

Packaging

|

|

Jar

|

Cartridge

|

Syringe

|

|

250 g

500 g

|

600g

1,2 Kg

|

30 g

|

100 g

|

|

EcorelTM Free 105-16

|

SAC105Ni

|

Very good wetting on any surface finish

Strong anti-graping properties

Robust assembly process for high volume

Outstanding first pass yield testability

Very low voiding

Transparent and colorless residue even after multiple reflow cycles

|

√

|

|

√

|

|

√

|

√

|

√

|

|

|

|

EcorelTM Free 105-21

|

SAC105Ni

|

Chemically inert residue, minimizing the risk of corrosion mechanisms and leakage current

Good compatibility with a large range of conformal coating in the market

Bono corrosion test compliant

|

√

|

√

|

√

|

|

√

|

√

|

√

|

|

|

|

EcorelTM Free 007-15

|

SnCu0.7 + dopants

|

For dispensing application

Standard reflow and selective soldering

|

√

|

|

|

√

|

|

|

|

|

√

|

|

EcorelTM Free 007-16

|

SnCu0.7 + dopants

|

Very Low solder void percentage

Excellent visual solder joint cosmetics

High first pass yield testability in ICT and FP

|

√

|

|

√

|

|

√

|

√

|

√

|

|

|

|

EcorelTM Free 007-21

|

SnCu0.7 + dopants

|

Chemically inert residue, minimizing the risk of corrosion mechanisms and leakage current

Good compatibility with a large range of conformal coating in the market

Bono corrosion test compliant

|

√

|

√

|

√

|

|

√

|

√

|

√

|

|

|

| EcorelTM Free LT140-18 |

SnBiAg |

Recommended for temperature sensitive components Excellent solder joint strength

Low energy consumption during reflow process

|

√ |

|

√ |

|

|

|

|

|

|

CÁC SẢN PHẨM KHÁC CÙNG NHÀ SẢN XUẤT / OTHER PRODUCTS FROM Inventec |

|

|

| | |

ĐỐI TÁC QUỐC TẾ

Minato, Leap, SMH-Tech, Xeltek, Elnec, Conitec, DediProg, Phyton, Hilosystems, Flash Support Group, PEmicro || Rigol, Tonghui, Copper Mountain, Transcom, APM || Atten, Zhuomao, Puhui, Neoden, Ren Thang, Genitec, Edry, UDK ||

|

ENGLISH

ENGLISH Trang chủ

Trang chủ

Ecorel Free 305-16 T4: Solder paste - Kem hàn Type 4, có 3% bạc (Inventec)

Ecorel Free 305-16 T4: Solder paste - Kem hàn Type 4, có 3% bạc (Inventec)