| Device Programmers |

| Universal Programmer |

| Gang Programmer ¦ |

| In-System Programmer |

| Specialized Programmer |

| Auto. Handler System |

| Sockets and Accessories |

| Eprom Eraser, IC Tester |

| HDD/memory Duplicator |

| Jig test ICT/FCT/DIP-pallet |

| Test and Measurement |

| Osciloscope, HDS, MSO |

| Spectrum/Network/Logic |

| Data Logger and Sensors |

| Digital Multimeter |

| Generator, Freq. couter |

| LCR, component tester |

| Power Supply, elec. load |

| Design, Assembly Tools |

| Training & Education KIT |

| Embedded Dept. Tools |

| Rework & Solder tools |

| SMT/ PCBA Equipments |

| Other electronics Tools |

| Automotive Tools |

| Telecom, Television |

| Optical, Force, Torque |

| Electronics components |

| MCU 8051-core series |

| Nuvoton ARM Cortex-M |

| Voice and Audio ICs |

| Nuvoton ARM7/9 Soc |

| Wireless RF IC, Tools |

|

|

|

We received

238665058

page views since 20/12/2006 |

There are currently, 0 guest(s) and 0 member(s) that are online.

You are Anonymous user. You can register for free by clicking here |

OUR PARTNERS

(Products Line-Card)

|

| |

Category: Main/3. Electronics Equipments & Systems for embedded electronics design and PCB assembly/3.3. Solder Tools and rework systems

| | | | | ◊ Đặc điểm chính: | | The “Desktop Infrared Reflow Oven” is equipment that used for electron production and maintain of SMT technique. The product adopts the far-infrared heating components and excellent sense temperature materials. Through the precise control of the microcomputer, make the temperature control curve match to the request of the SMT production technique completely. The “temperature control curve” of the equipment can be adjusted accurately, so it can satisfy the request of many kinds of soldering paste which are different material parameters. It can shut down and alarm the faults automatically. Also it has many functions, such as soldering, maintenance and drying.

"Máy hàn đối lưu hồng ngoại cho linh kiện dán" này là thiết bị dùng cho sản xuất điện tử và bảo trì công nghệ SMT. Sản phẩm này đáp ứng cho linh kiện cần gia nhiệt hồng ngoại và các vật liệu nhạy cảm cao về nhiệt độ. Nhờ sự điều khiển chính xác của máy vi tính, khiến cho điều khiển nhiệt độ có đặc tuyến phù hợp hoàn toàn với yêu cầu của công nghệ sản xuất SMT. Đặc tuyến điều khiển nhiệt độ này của thiết bị có thể được hiệu chỉnh một cách chính xác, bởi vậy nó có thể thoả mãn yêu cầu của nhiều kiểu kem hàn (solder-paste) có các tham số vật liệu khác nhau. Nó có thể tắt và cảnh báo lỗi một cách tự động. Nó cũng có nhiều tính năng, như là hàn, bảo trì và làm khô. |

|

|

Product Description  Features & Details - 1. This machine selects the intelligent level sirocco and rapid infrared heating technology controlling, equipped with special design wind wheel, speed stability and uniform temperature, suit for uninterrupted soldering the LED and BGA components.

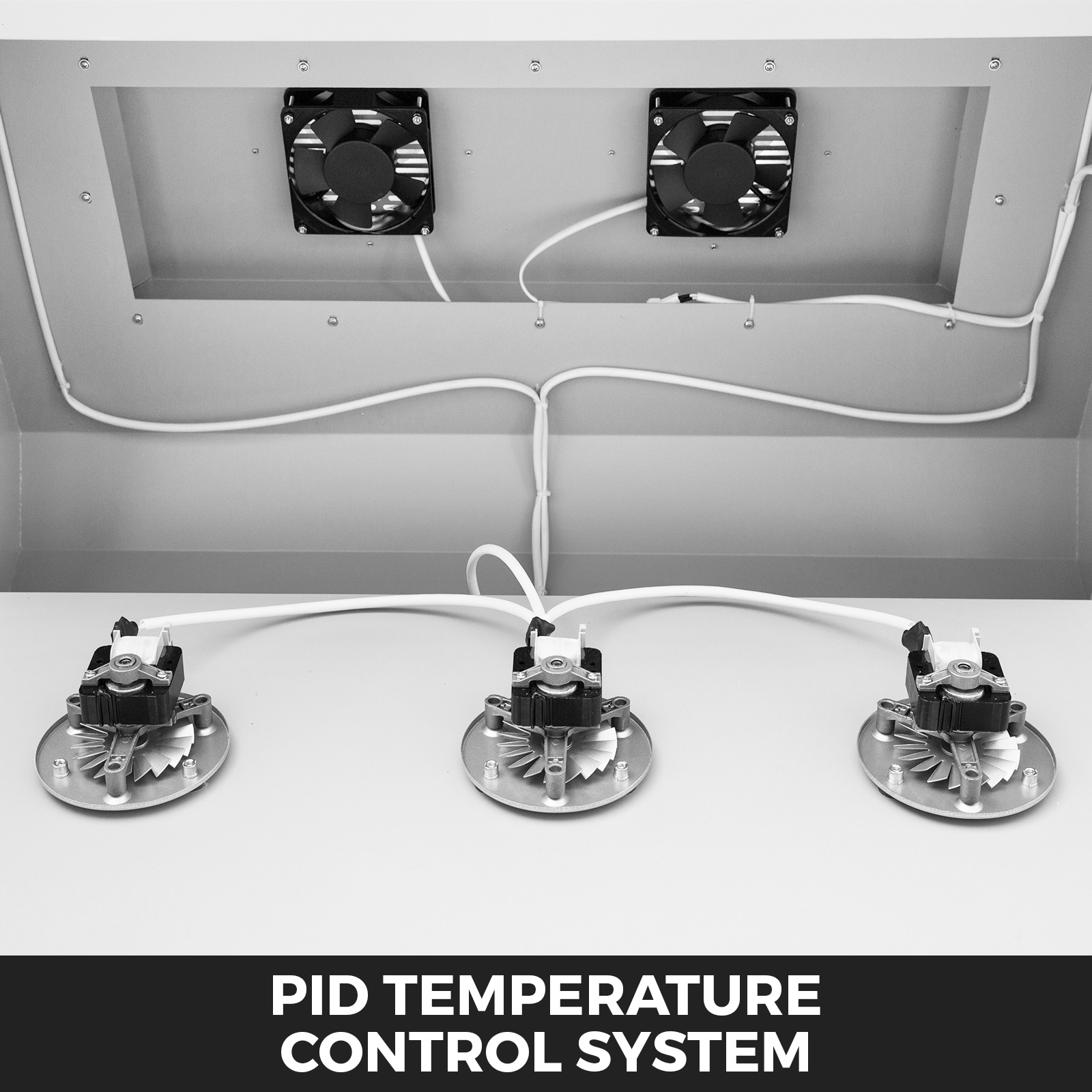

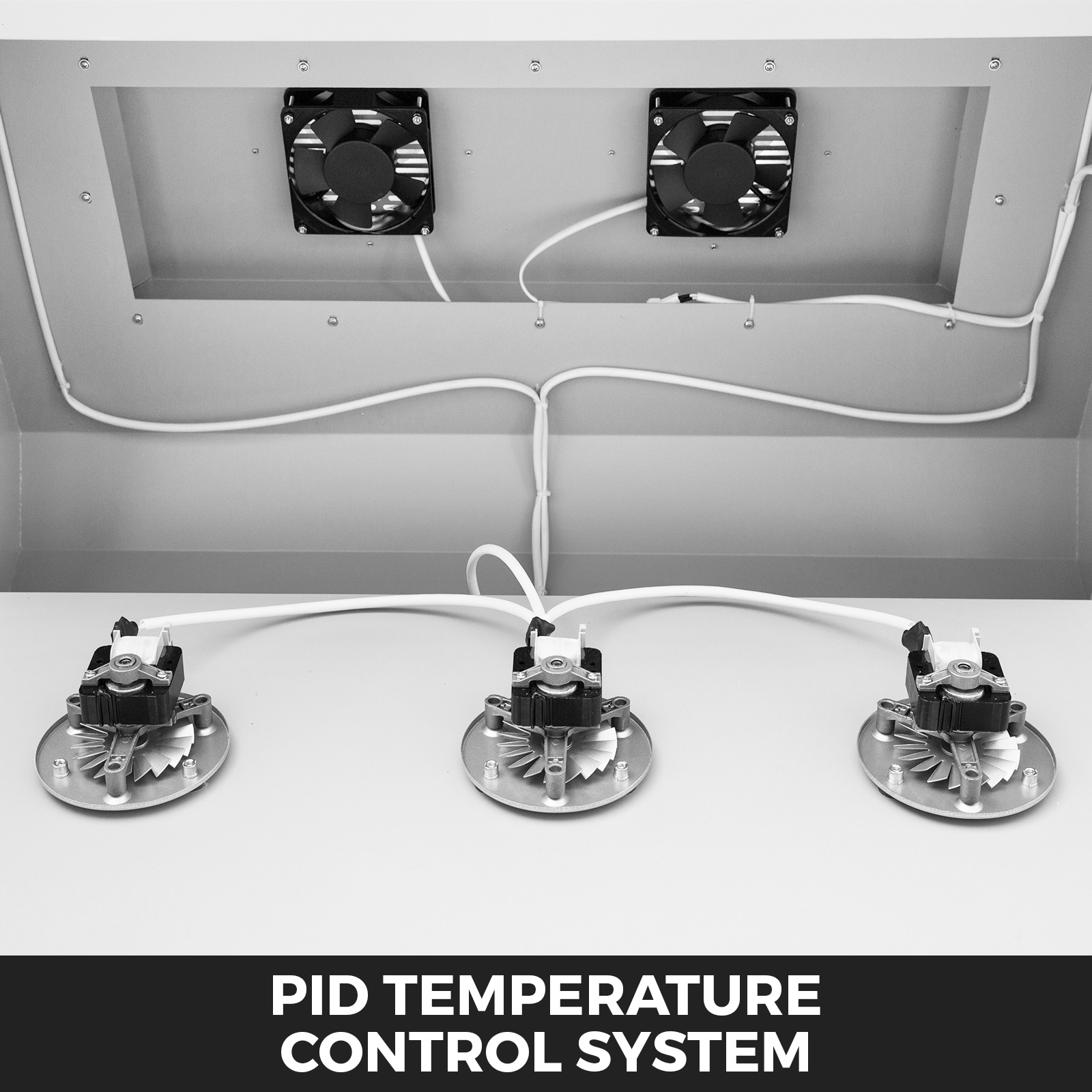

- 2. This machine is equipped with the crawler-type and five temperature area heating systems, and each temperature area uses independent PID controlling and up-down heating type, can make the inside temperature more accurate and well-proportioned, just take about 20 minutes can let it heat up to the working temperature from the room temperature.

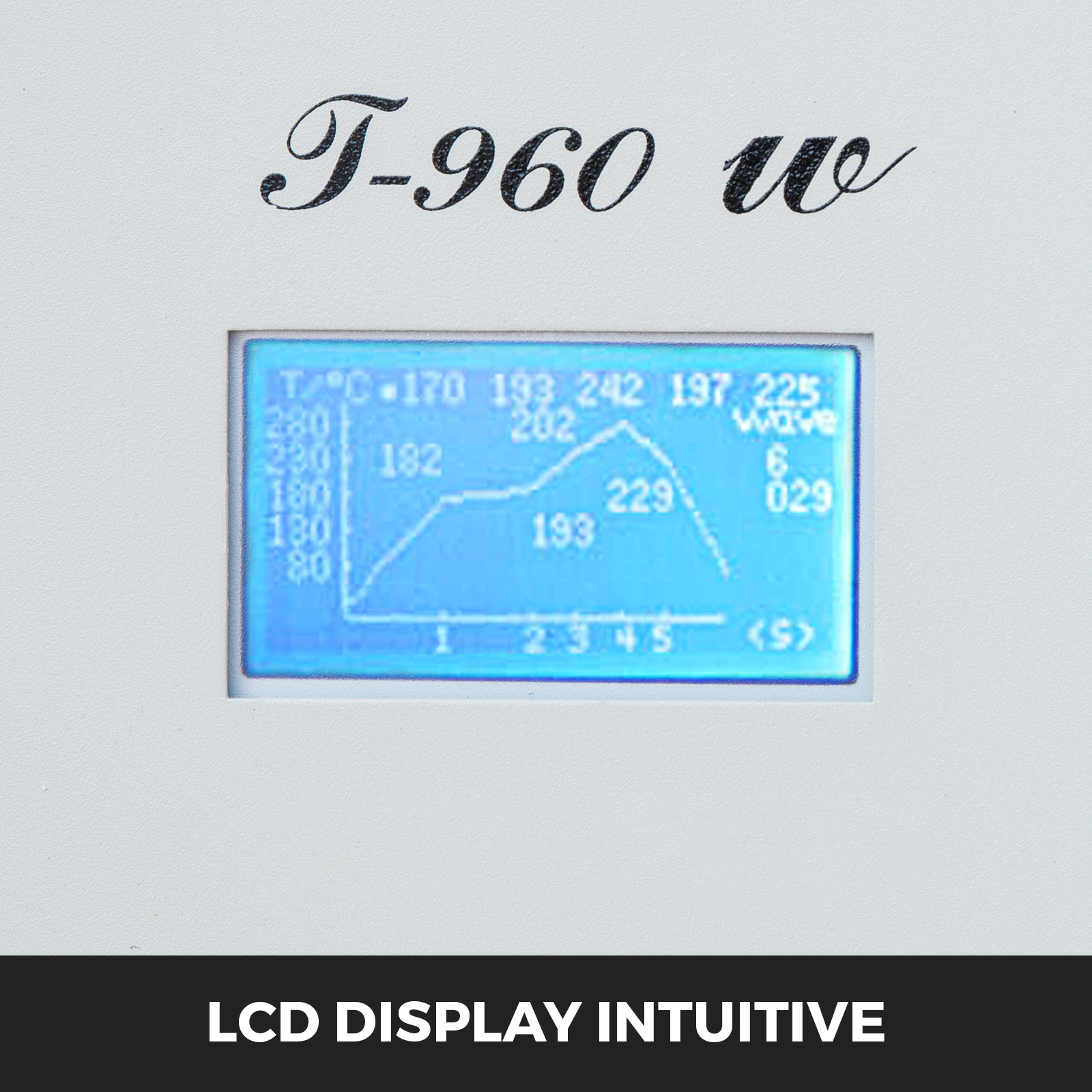

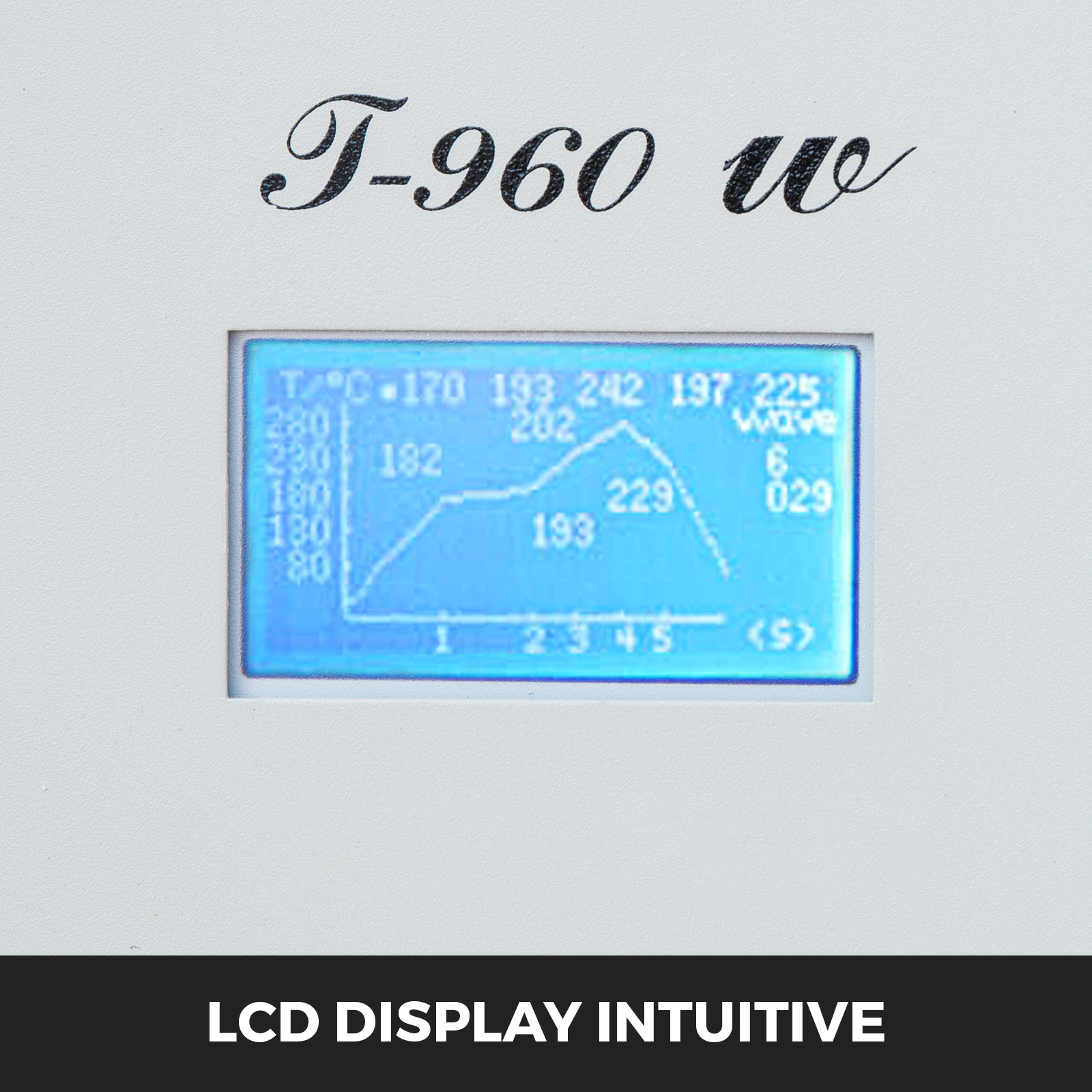

- 3. Intelligent temperature wave heating type, oversized capacity wave selection, have eight temperature waves can satisfy various welding technological requirements.

- 4. Use programmable technology, preset the temperature wave memory storage function, can complete the whole welding process automatically according to your presetting wave.

- 5. Adopt the thermocouple temperature measurement and add the compensation circuit, make the temperature measurement more accurate, the wave more perfect.

- 6. Use PID intelligent temperature control technology; make the temperature control more accurately. Adopt the imported large current solid-state relay non-contact output can effectively avoid the IC or circuit board damage due to the rapid or uninterrupted warming up, make the whole welding process more scientific safety.

- 7. Transmission system adopt imported frequency conversion motor, PID closed-loop speed, equip with all the import 1:150 turbine speed reducer, smooth operation, speed adjustable range 0-1600mm/min.

- 8. Adopt independent wheel structure and special stainless steel strut, durable wear-resisting runs smoothly, speed precision can reach ±10mm/min.

- 9. Independent cooling zone, to ensure the PCB board of low temperature when the required.

- 10. Friendly human-machine operation interface, perfect LCD display, no need to connect with the PC, can watch the whole repairing process very clearly.

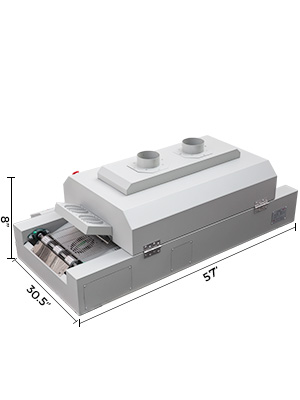

- 11. Ergonomic design, practical and easily operated. Good build quality but at the same time light weight and a small footprint allows the T-960W to be easily bench positioned, transported or stored.

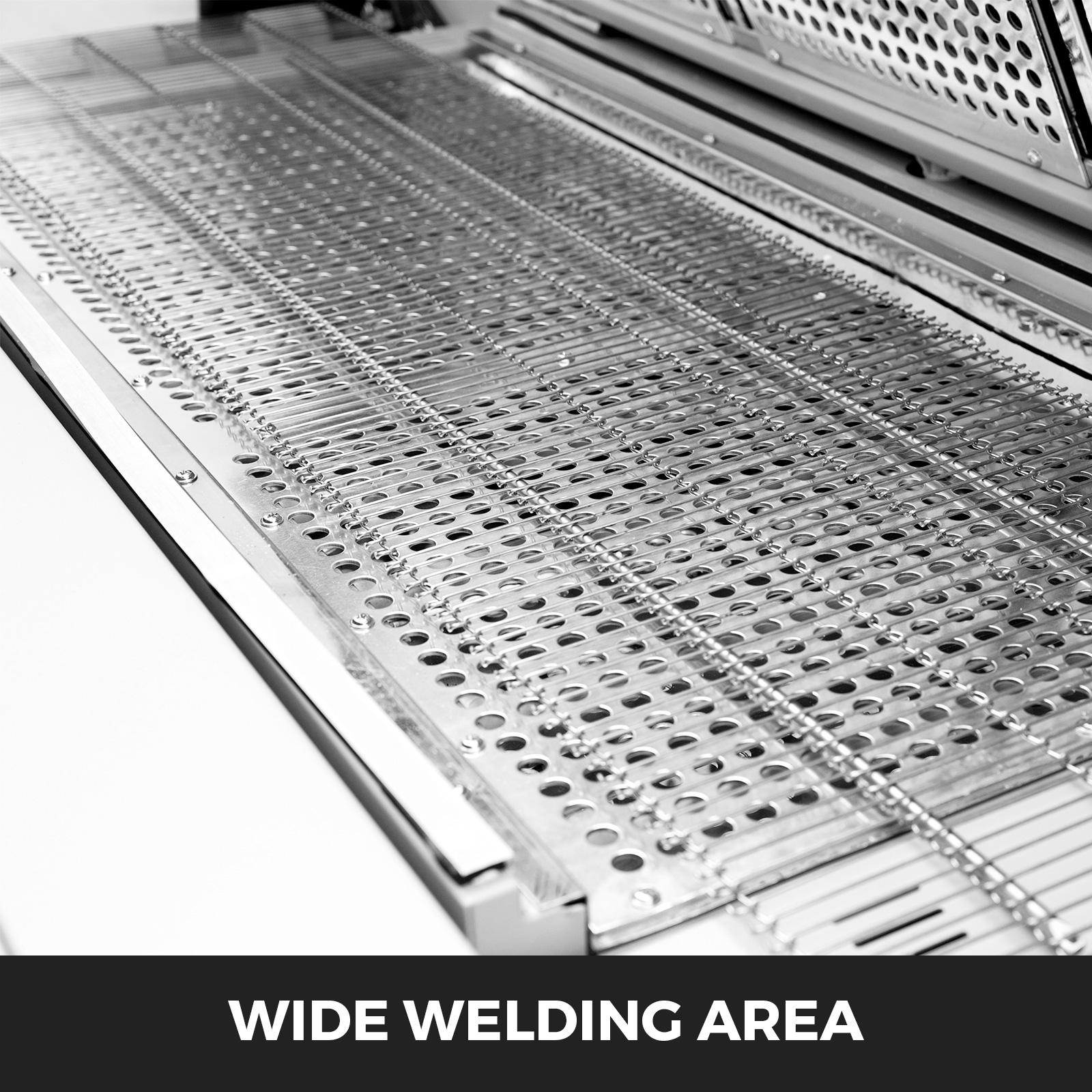

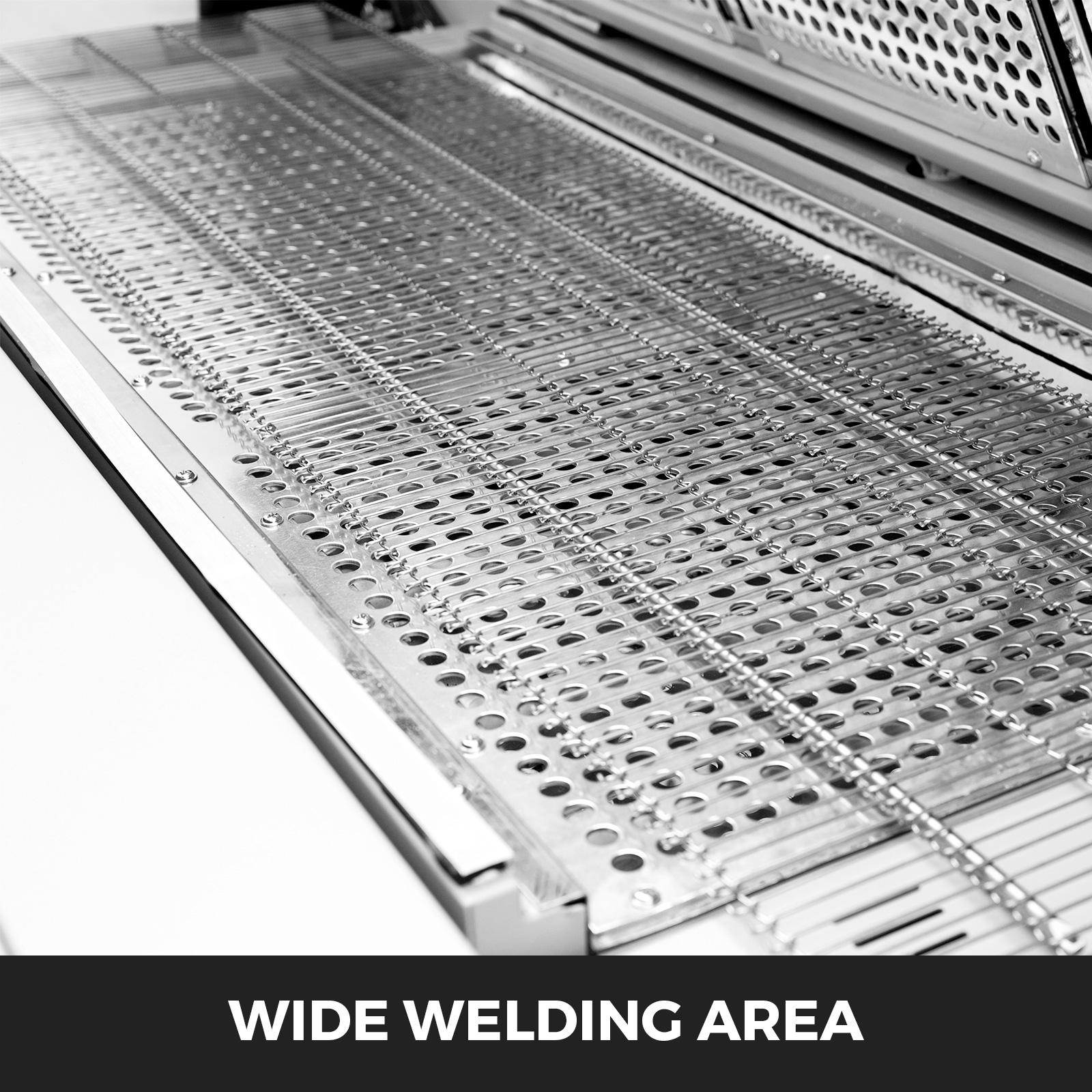

Key Features Wide working area of 300x960mm, thus allowing it to work under different working condition, making it all-in-one device you want, large welding area for high efficiency. This increases the usage range of this machine drastically and makes it an economical investment.

- PID Temperature Control System

Adopting PID closed-loop control, each temperature area uses independent PID controlling and up-down heating type, can make the inside temperature more accurate and well-proportioned, only need 20 minutes can let it heat up to the working temperature from the room temperature.  Automatic Soldering Process Use programmable technology, eight soldering cycles are predefined and the entire soldering process can be completed automatically from Preheat, soak and reflow through to cool down. Uses up to 4500 W of energy efficient Infrared heating and air circulation to re-flow solder

Independent Roller Structure Adopt independent wheel structure with special stainless steel conveyor belt and strut, durable wear-resisting runs smoothly, speed precision can reach ±10mm/min. Independent cooling zone, to ensure the PCB board of low temperature when the required.

LCD display intuitive every data such as speed, time, temperature. Friendly human-machine operation interface, no need to connect with the PC, can watch the whole repairing process very clearly, convenient and intuitively.

Outside-load operation panel, avoids highly temperature in the panel to improve stability, convenient to operate. Ergonomic design, practical and easily operated. Good build quality, compact size, allows it to be easily bench positioned, transported or stored.

Main technique parameter

Model

| T-960W

| The heating zone quantity

| upper 3 / down 2

| | The length of the heating zone | 960mm (Chiều dài của ngăn gia nhiệt) | The heating type

| intelligent level sirocco and rapid infrared heating

| The cooling zone quantity

| 1 (Số lượng ngăn làm mát)

| Maximum width of PCB board

| 300MM (Chiều rộng tối đa bo mạch PCB)

| The operation direction

| left→right (Hướng vận hành Trái -> Phải)

| Delivery options

| Net transmission+chain transmission

| The speed of conveyer belt

| 0-1600mm/min (Tốc độ băng tải hàn) | The power supply

| Three phase 5 line 380V 50/60Hz

380V50/60Hz | Peak power

| 4.5KW (Công suất tối đa) | Heating up time

| Around 15mins

| Temperature control range

| Room temperature~350℃

| Temperature control mode

| PID closed-loop control

| Temperature control accuracy

| ±1℃ (Độ chính xác điều khiển nhiệt độ)

| PCB temperature distribution deviation

| ±2℃

| Overall dimensions

| 1450×630×470mm (Kích thước máy)

| Machine weight

| 160KGS (Trọng lượng máy)

|

CÁC SẢN PHẨM KHÁC CÙNG NHÀ SẢN XUẤT / OTHER PRODUCTS FROM PUHUI |

|

|

| | |

OUR GLOBAL PARTNERS

Minato, Leap, SMH-Tech, Xeltek, Elnec, Conitec, DediProg, Phyton, Hilosystems, Flash Support Group, PEmicro ||Rigol, Tonghui, Copper Mountain, Transcom, APM || Atten, Zhuomao, Puhui, Neoden, Ren Thang, Genitec, Edry, UDK ||

CONDITTION AND USING TERMS

TULA Solution Co., Ltd - Công ty TNHH Giải pháp TULA

Headquater: No. 173 Group 15, Dong Anh District, Hanoi 10000, Vietnam

Head-Office: No. 6 Lane 23, Đình Thôn street, Mỹ Đình ward, Nam Từ Liêm Dist., Hà Nội, Vietnam

Tel.: +84-24.39655633, Hotline: +84-912612693, E-mail: info (at) tula.vn |

TIẾNG VIỆT

TIẾNG VIỆT Home

Home

T-960W: SMT Infrared Reflow Oven (Máy hàn đối lưu hồng ngoại)

T-960W: SMT Infrared Reflow Oven (Máy hàn đối lưu hồng ngoại)