| Device Programmers |

| Universal Programmer |

| Gang Programmer ¦ |

| In-System Programmer |

| Specialized Programmer |

| Auto. Handler System |

| Sockets and Accessories |

| Eprom Eraser, IC Tester |

| HDD/memory Duplicator |

| Jig test ICT/FCT/DIP-pallet |

| Test and Measurement |

| Osciloscope, HDS, MSO |

| Spectrum/Network/Logic |

| Data Logger and Sensors |

| Digital Multimeter |

| Generator, Freq. couter |

| LCR, component tester |

| Power Supply, elec. load |

| Design, Assembly Tools |

| Training & Education KIT |

| Embedded Dept. Tools |

| Rework & Solder tools |

| SMT/ PCBA Equipments |

| Other electronics Tools |

| Automotive Tools |

| Telecom, Television |

| Optical, Force, Torque |

| Electronics components |

| MCU 8051-core series |

| Nuvoton ARM Cortex-M |

| Voice and Audio ICs |

| Nuvoton ARM7/9 Soc |

| Wireless RF IC, Tools |

|

|

|

We received

238984443

page views since 20/12/2006 |

There are currently, 0 guest(s) and 0 member(s) that are online.

You are Anonymous user. You can register for free by clicking here |

OUR PARTNERS

(Products Line-Card)

|

| |

Category: Main/3. Electronics Equipments & Systems for embedded electronics design and PCB assembly/3.4 SMT Line System

| | | | | ◊ Đặc điểm chính: | | Specific application: 1) Defect inspection in IC encapsulation, e.g.: layer separation, cracking, void, and line integrity. 2) Measuring chip size, measuring line curvature, measuring the proportion of solder area of components. 3) Possible defects in PCB manufacturing processes, e.g.: misalignment, solder bridge and open. 4) SMT solder short, cold solder, component shifted, solder insufficient, solder void inspection and measurement. 5) Defect inspection of open, short or abnormal connections that may occur in automotive wiring harnesses and connectors. 6) Inner rupture or hollow inspection in plastic or metal. 7) Battery stacking uniformity, electrode welding inspection. 8) Seed, biological material inspection etc.

|

|

|

Ứng dụng cụ thể: 1) Kiểm tra khuyết tật trong quá trình đóng gói vi mạch, ví dụ: tách lớp, nứt, khoảng trống và tính toàn vẹn của dòng. 2) Đo kích thước phoi, đo độ cong đường, đo tỷ lệ diện tích hàn của linh kiện. 3) Các khiếm khuyết có thể xảy ra trong quy trình sản xuất PCB, ví dụ: lệch trục, cầu hàn và hở. 4) Mối hàn SMT ngắn, mối hàn nguội, thành phần bị dịch chuyển, vật hàn không đủ, kiểm tra và đo khoảng trống mối hàn. 5) Kiểm tra khiếm khuyết của các kết nối hở, ngắn hoặc bất thường có thể xảy ra trong dây nịt và đầu nối của ô tô. 6) Kiểm tra vết nứt hoặc rỗng bên trong bằng nhựa hoặc kim loại. 7) Tính đồng nhất của pin, kiểm tra hàn điện cực. 8) Kiểm tra hạt giống, vật liệu sinh học, v.v.

Applications of X-Ray X-Ray inspection system is high-precision detection equipment. It inspects and analyzes the inner structure of the object without damage via the penetration power from X-Ray. It has been widely applied to BGA detection, LED, SMT, semiconductor, battery, automotive electronics, ceramic products, casting, plastic, connectors, pharmaceutical products and other industries. Main Functions

|

Function

|

Advantages

|

|

X-ray tube and detector can move along Z direction

|

Fault less than 2.5μm can be detected.

|

|

Voltage and current set by software

|

Easy to maintain, long service life.

|

|

Speed of table moving along X-Y direction can be adjusted.

|

Easy operation, training time for operator is short.

|

|

Powerful CNC Measuring Function, can test automatically, testing program can be edited.

|

Suitable for mass detection

|

|

High-definition digital flat panel detector.

Max Inclined Angle is 60°

|

semi-automatic identification for OK/NG products.

|

|

Large navigation view, table will move to where you click the mouse.

|

Highly reliable and high-precision test

|

|

Latest image processing technology, can numerically calculate the size of the defect and area size.

|

Suitable to different samples with large sizes.

|

|

Accurately detect insufficient solder/cold solder and blob ratio of PCB board, can also calculate the size, import the result into the sheet and display on the screen.

|

samples can be observed with a unique perspective

|

Technical Parameters

|

Items

|

|

Contents

|

|

Model

|

|

X-6600

|

|

Japan Hamamatsu X-RAY launch tube

|

Tube type

|

Closed X-ray tube

|

|

Maximum tube voltage

|

90kV (130kV Optional)

|

|

Maximum tube current

|

0.12mA

|

|

Focal spot size

|

5μm

|

|

Magnification

|

Geometric magnification:150X

System magnification:1000X

|

|

Korea Rayence Flat Panel Detector

|

Image speed

|

30 fps

|

|

Resolution

|

1176*1104

|

|

Inclined Angle

|

60°

|

|

Cabinet Specifications

|

Table size

|

500mm*450mm

|

|

Dimension

|

Length: 1360mm, width: 1360mm, height: 1650mm

|

|

Net weight

|

1300kg

|

|

Input voltage

|

AC 110-220V (+10%) (international standard power supply)

|

|

X-ray leakage amount

|

≤1 u Sv/h

|

|

Operating system

|

Windows 7 Seamark3.0

|

|

Total power

|

1700W

|

Standard Configuration

|

Name

|

QTY

|

Unit

|

Remark

|

|

90KV-5um Closed X Tube

|

1

|

Pcs

|

(130kV Optical)

|

|

Object Table

|

1

|

Pcs

|

size:500mm*450mm

|

|

Flat Panel Detector

|

1

|

Pcs

|

HD

|

|

Image processor CPU

|

1

|

Pcs

|

Complete function

|

|

LCD

|

1

|

Pcs

|

24’’

|

Object Table Control

1. Speed of table can be adjusted by the spacebar: low, normal and high speed.

2. X, Y, Z three-axis motion and inclined angle are controlled by keyboard.

3. Users can control the table speed and angle programmatically.

4. Large navigator view, clear navigation image, table will move to where you click the mouse.

NC Programming

1. Simply click the mouse and you can write programs.

2. Object table moves along X, Y direction for positioning; X-ray tube and detector move along Z direction for positioning.

3. Voltage and current set by software.

4. Image settings: brightness, contrast, auto gain and exposure.

5. Users can change the pause time for program conversion.

6. Anti-collision system can maximize the tilt and observation of the workpieces.

7. Automatical analysis on diameter, proportion of cavity, area and roundness of BGA.

Full Automatic Testing Procedures

Click programming without the need for operator intervention on the component can detect automatically.

Packaging:

Fumigating-free Plywood crate.

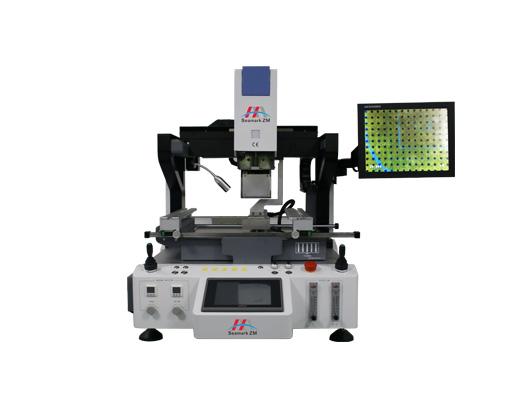

CÁC SẢN PHẨM KHÁC CÙNG NHÀ SẢN XUẤT / OTHER PRODUCTS FROM Zhuomao |

|

|

| | |

OUR GLOBAL PARTNERS

Minato, Leap, SMH-Tech, Xeltek, Elnec, Conitec, DediProg, Phyton, Hilosystems, Flash Support Group, PEmicro ||Rigol, Tonghui, Copper Mountain, Transcom, APM || Atten, Zhuomao, Puhui, Neoden, Ren Thang, Genitec, Edry, UDK ||

CONDITTION AND USING TERMS

TULA Solution Co., Ltd - Công ty TNHH Giải pháp TULA

Headquater: No. 173 Group 15, Dong Anh District, Hanoi 10000, Vietnam

Head-Office: No. 6 Lane 23, Đình Thôn street, Mỹ Đình ward, Nam Từ Liêm Dist., Hà Nội, Vietnam

Tel.: +84-24.39655633, Hotline: +84-912612693, E-mail: info (at) tula.vn |

TIẾNG VIỆT

TIẾNG VIỆT Home

Home

X-6600: Automated x-ray inspection system (Hệ thống kiểm tra tự động bằng X-Ray)

X-6600: Automated x-ray inspection system (Hệ thống kiểm tra tự động bằng X-Ray)