| Device Programmers |

| Universal Programmer |

| Gang Programmer ¦ |

| In-System Programmer |

| Specialized Programmer |

| Auto. Handler System |

| Sockets and Accessories |

| Eprom Eraser, IC Tester |

| HDD/memory Duplicator |

| Jig test ICT/FCT/DIP-pallet |

| Test and Measurement |

| Osciloscope, HDS, MSO |

| Spectrum/Network/Logic |

| Data Logger and Sensors |

| Digital Multimeter |

| Generator, Freq. couter |

| LCR, component tester |

| Power Supply, elec. load |

| Design, Assembly Tools |

| Training & Education KIT |

| Embedded Dept. Tools |

| Rework & Solder tools |

| SMT/ PCBA Equipments |

| Other electronics Tools |

| Automotive Tools |

| Telecom, Television |

| Optical, Force, Torque |

| Electronics components |

| MCU 8051-core series |

| Nuvoton ARM Cortex-M |

| Voice and Audio ICs |

| Nuvoton ARM7/9 Soc |

| Wireless RF IC, Tools |

|

|

|

We received

238532968

page views since 20/12/2006 |

There are currently, 0 guest(s) and 0 member(s) that are online.

You are Anonymous user. You can register for free by clicking here |

OUR PARTNERS

(Products Line-Card)

|

| |

Category: Main/4. Electronics Tools, KITs and other field Instruments/4.5. Compressed Air products

| | | | | ◊ Đặc điểm chính: | |

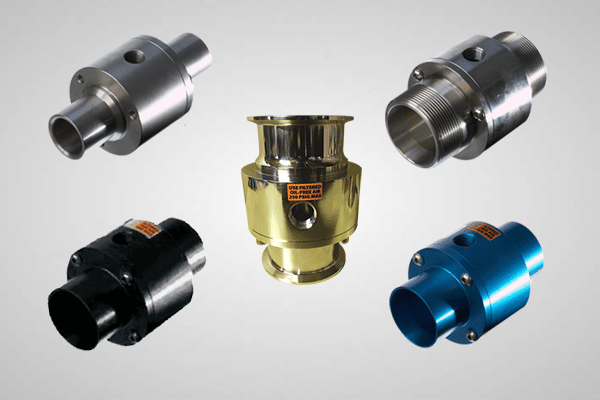

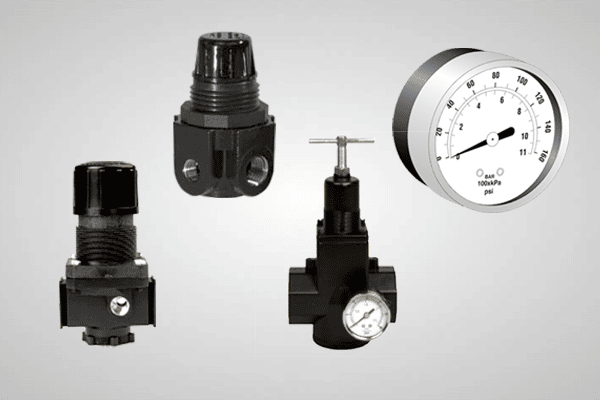

There are three standard sizes for the basic Frigid-X™ vortex tubes – the mini size which uses 2, 4 or 8 SCFM, the most common (medium) size which uses 10, 15, 25, 30 and 40 SCFM, and the large sizes which use 50, 75, 100 and 150 SCFM. The large sizes are used in heavy industry but can cool to over 10,000 BTU/hr. Vortex tubes normally come with the “hot end” adjustable to control the flow and temperature out the cold end. The more flow out the hot side, the lower the temperature out the cold side. It is important to note that the cooling effect (BTU/hr.) is determined by both flow and temperature drop. So if cooling effect is important, then the flow out the cold end should be between 60% – 80%. If the cold temperature is most important, then the flow out the cold end should be under 50%.

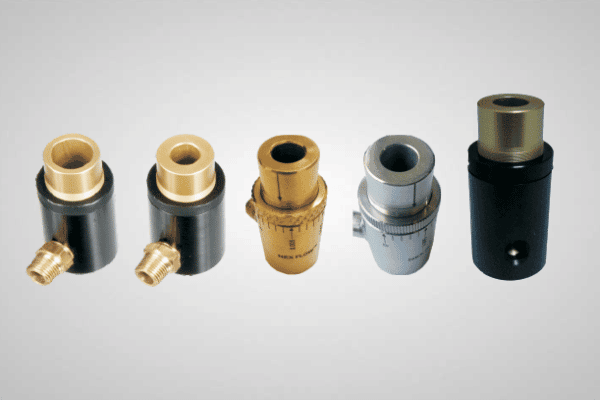

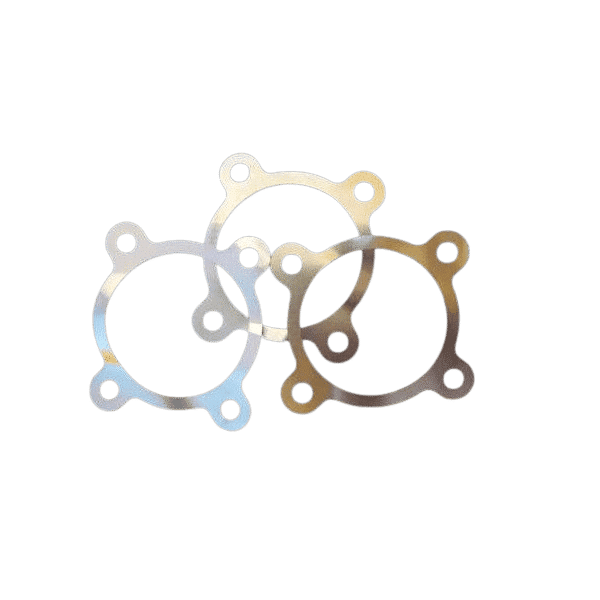

All vortex tubes have a “generator” which is sized for a certain flow. There are basically two kinds of generators- one for cooling effect and then a second kind which limits the flow out the cold end, to achieve very low temperatures. Depending on the temperature and pressure of the incoming compressed air, it is possible to achieve cold end temperatures as low as minus 40 and even minus 50 degrees F.

Applications

- Cool electronic and electrical control

- Cool machine operations/tooling

- Cool CCTV cameras

- Set hot melt adhesives

- Cool soldered parts

- Cool gas samples

- Cool heat seals

- Cooling environmental chambers

|

|

|

How Vortex Tubes work

Our Stainless Steel vortex tube comes assembled with a brass generator as a standard item rather than cheap plastic for a longer lifespan and for applications in high-temperature environments. With virtually no moving parts, the vortex tube takes compressed air and converts it to cold air as low as minus 50° F (minus 46° C) at one end and hot air at the other up to 260° F (127° C).

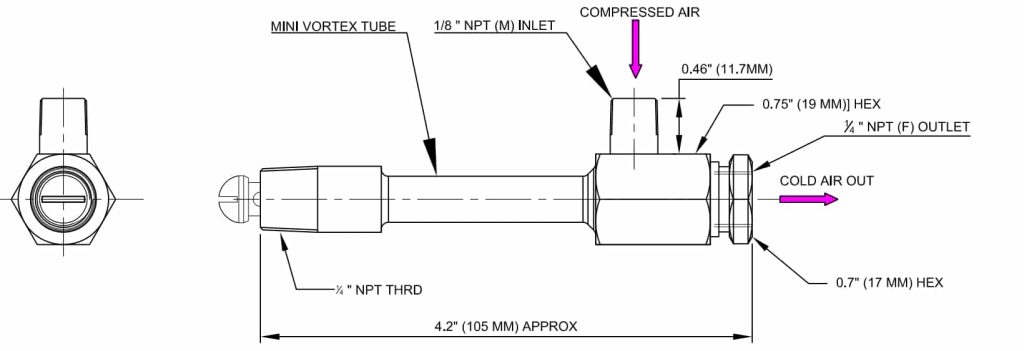

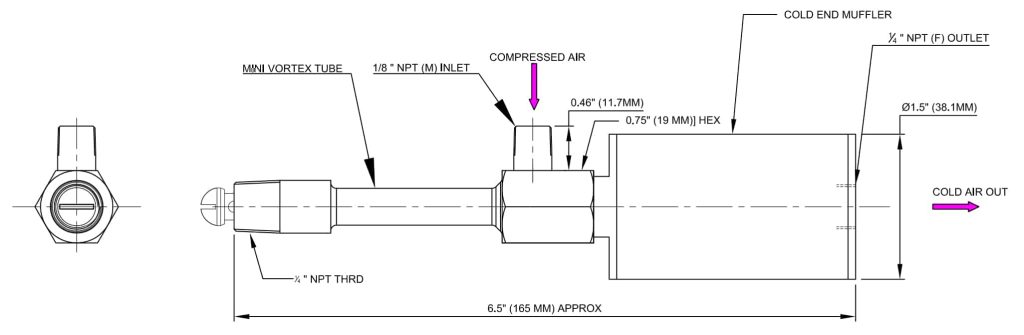

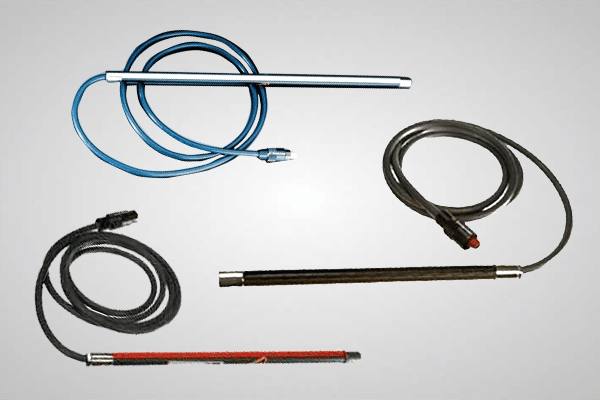

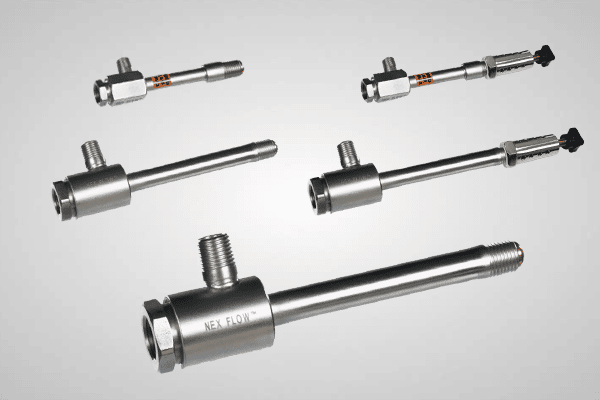

Small Vortex Tube

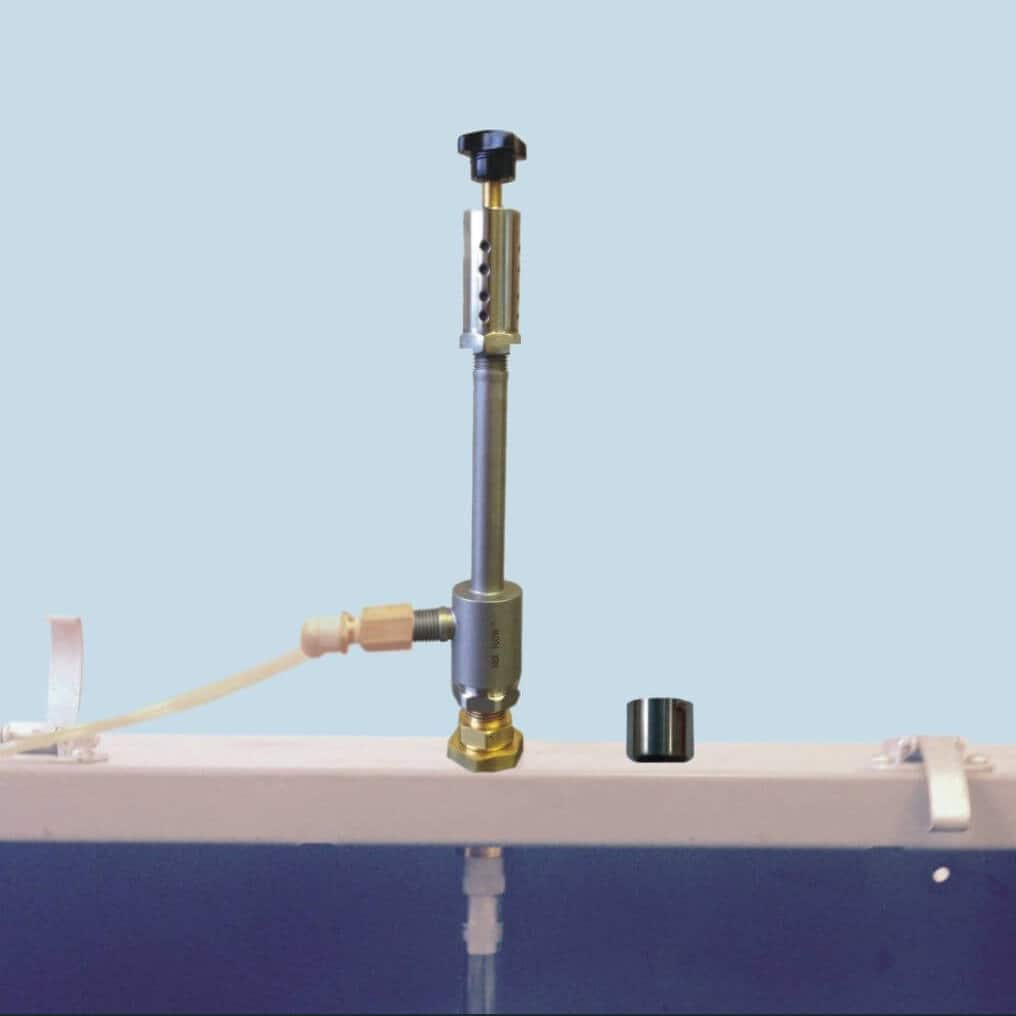

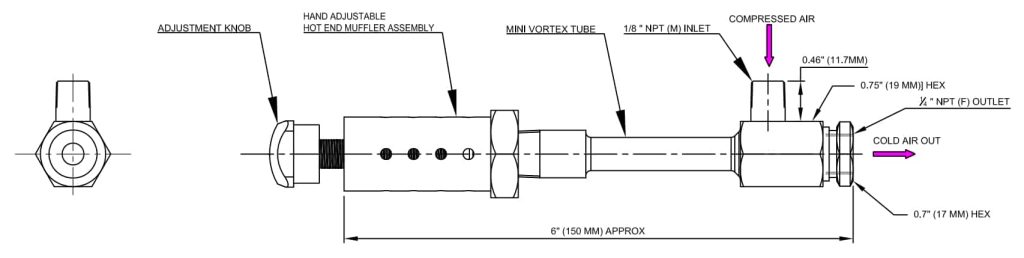

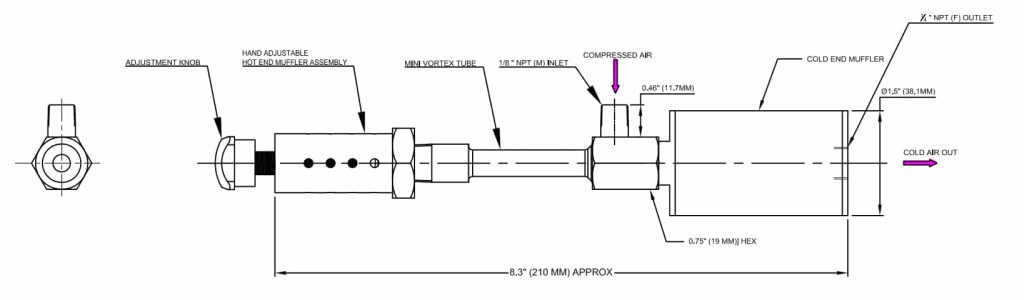

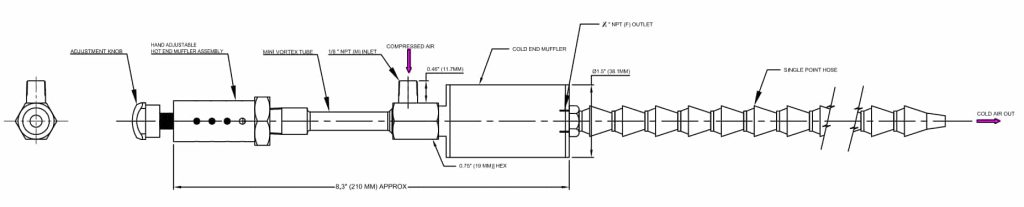

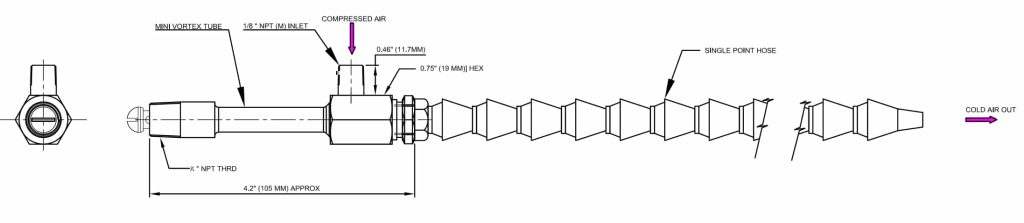

The small vortex tube size range (2- 8 SCFM) comes in two physical versions – with an adjustable hot end plug that is adjusted using a screwdriver and with a “hand adjustable knob” and a hot end muffler incorporated into the unit.

Medium Vortex Tube

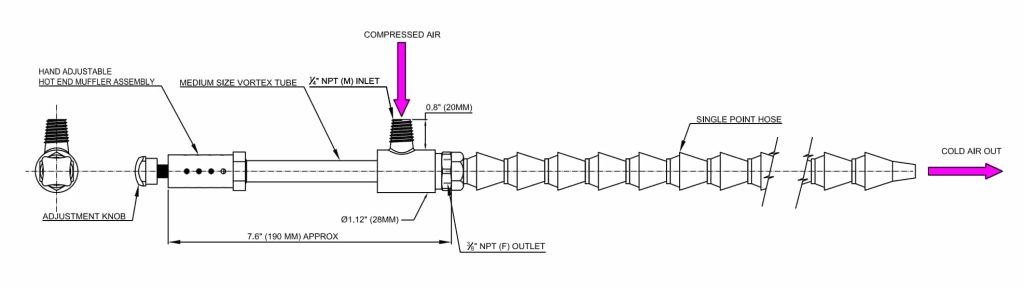

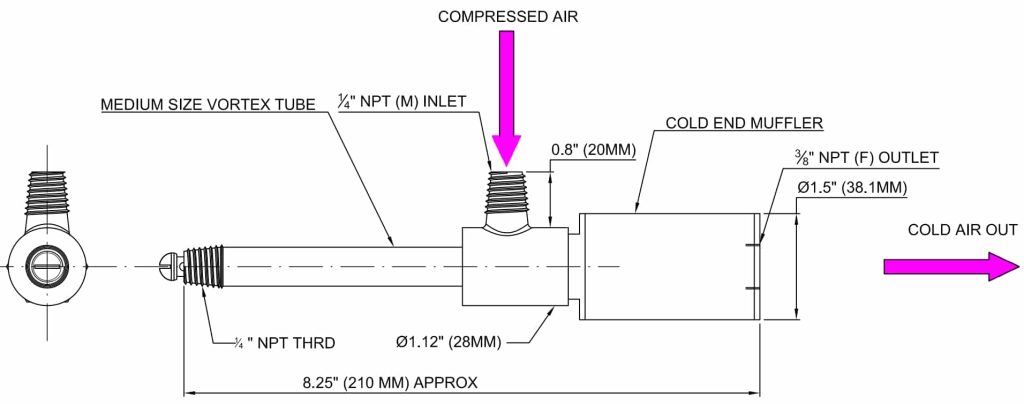

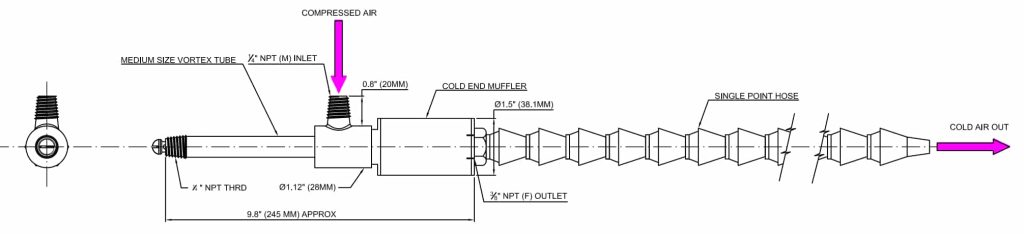

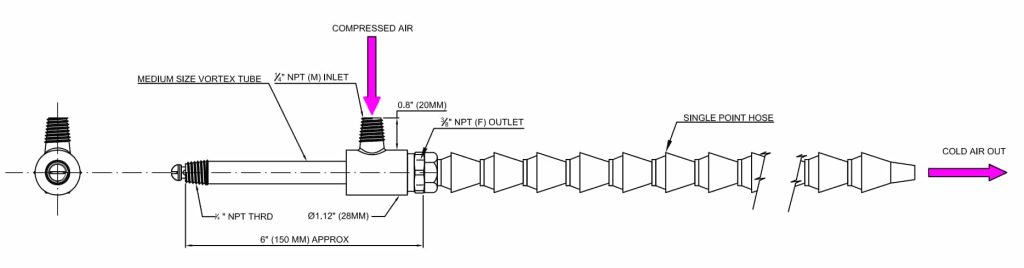

The medium vortex tube size range (10- 40 SCFM) also comes in two physical versions – with same adjustable hot end plug that is adjusted using a screwdriver and with the same “hand adjustable knob” and a hot end muffler incorporated into the unit.

For both the small and medium vortex tube you can easily convert the version that needs a screwdriver to the hand adjustable version, which ever is bets suited to the application.

Large Vortex Tube

The large vortex tube size range (50 -1150 SCFM) comes in one physical versions only with the adjustable hot end plug that is adjusted using a screwdriver.

Vortex tubes are most often purchase in the following packages:

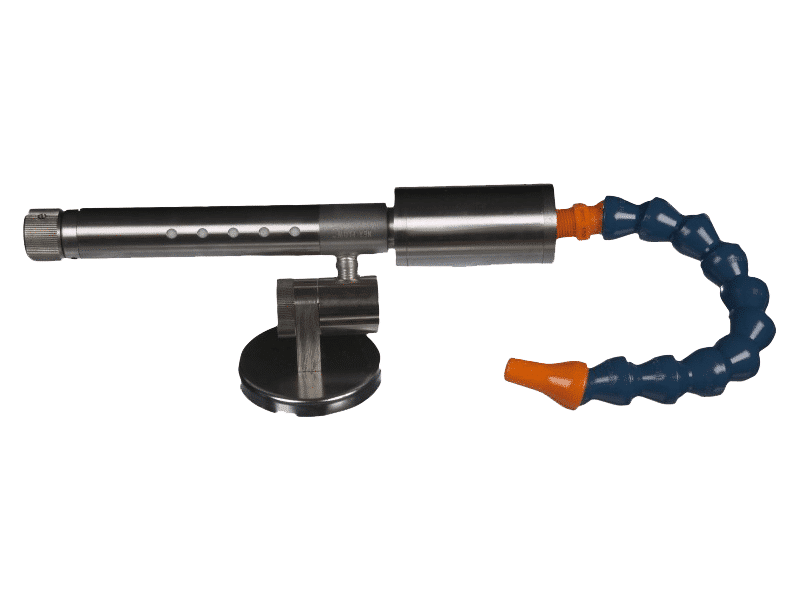

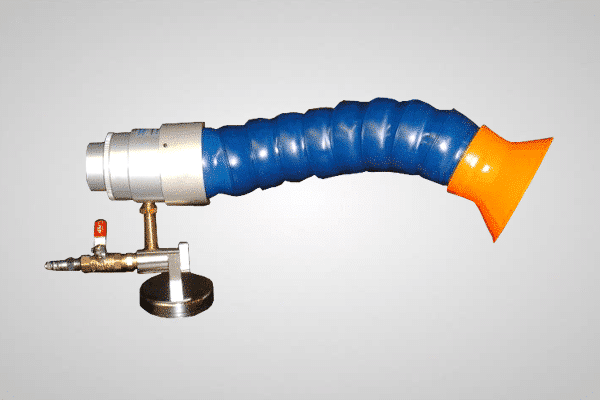

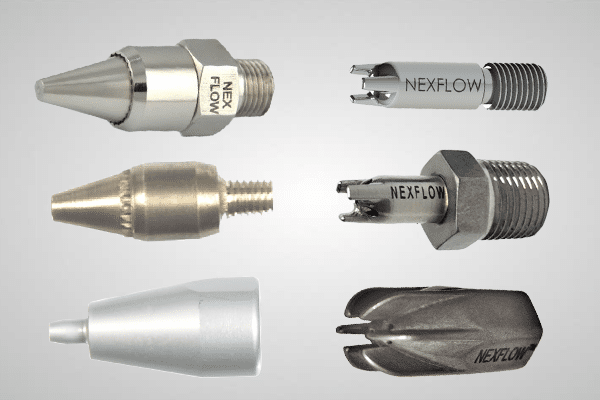

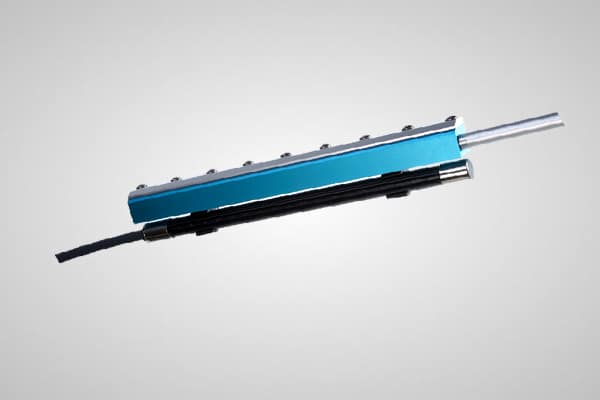

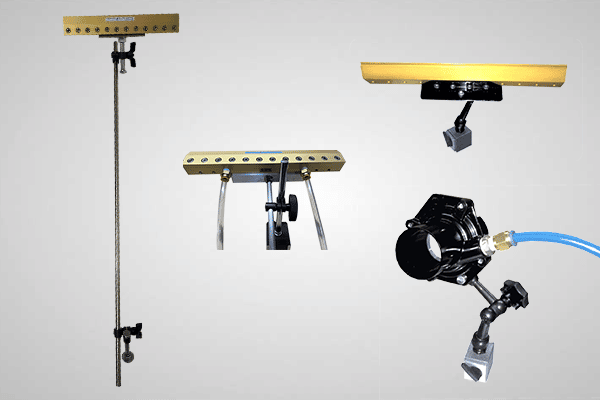

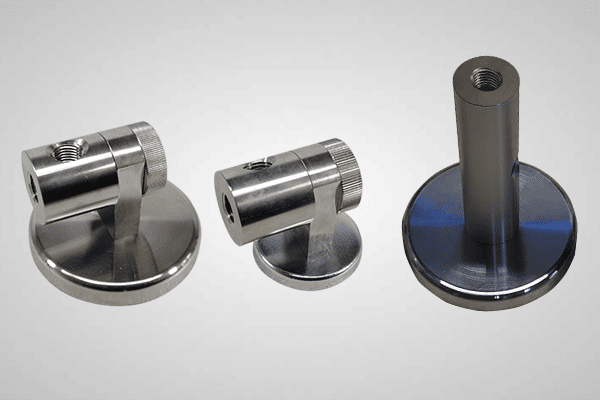

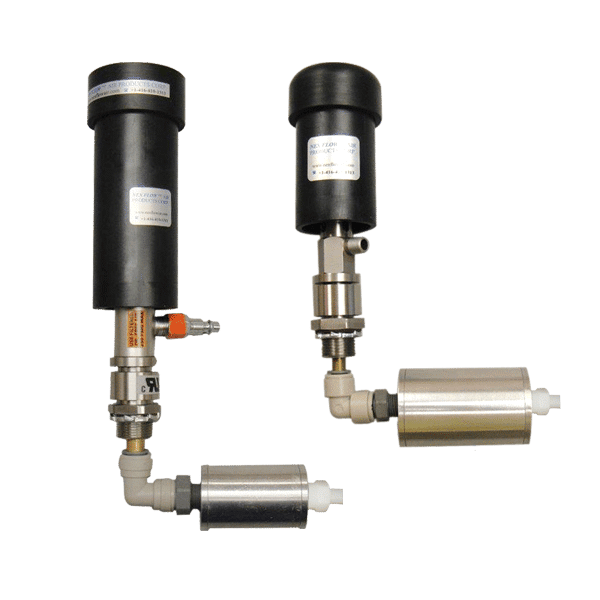

The Frigid-X™ Adjustable Spot Cooler is a low cost and maintenance free system which utilizes a vortex tube to produce cold air at one end. Comes complete with a magnetic base and generally used for laboratory testing or where temperature adjustment is required.

The Frigid-X™ Tool Cooler is designed for all types of dry machining applications for materials such as plastic, glass, ceramic, titanium, and others such as aluminum (if not deep hole drilling), and it has even been used for cooling needles in sewing and cutters for textile cutting. Another application is to cool slitters on plastic extrusion lines.

The Nex Flow™ Mini Spot Cooler is designed to cool small parts and produces a stream of 15 to 20 degree F (minus 9.5 to 7 degree C) of cold air to prevent heat buildup depending on inlet air temperature.

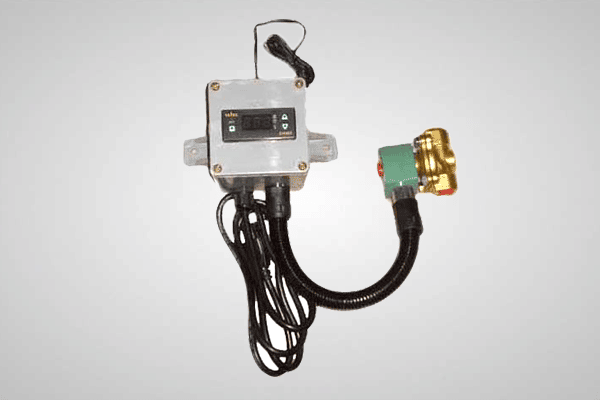

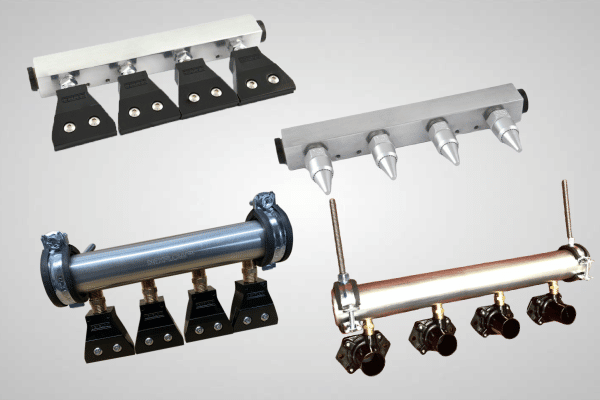

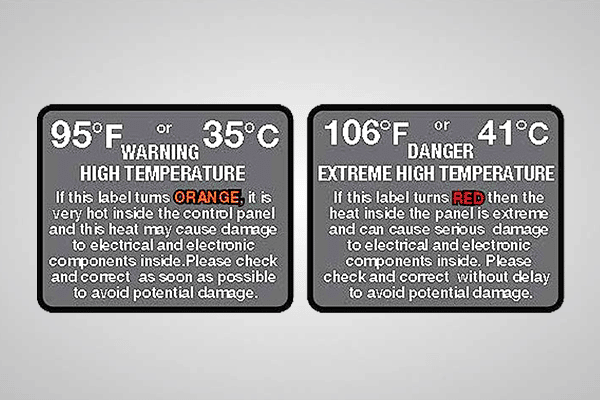

The Nex Flow™ Panel Cooler (Cabinet Enclosure Coors) is ideal for especially dirty and humid environments and where service is an issue with traditional industrial air conditioners

The X-stream Panel Cooler is a Cabinet Enclosure Cooler with extra sound muffling to maintain noise levels 65 dBA and under. Regular Panel Coolers may be converted to X-stream Panel Coolers by adding the Muffling Kit

For cooling small enclosures in laboratories , environmental chambers, and any application where an enclosure needs cooling.

Features / Advantages

-

No moving parts, reliable, maintenance free

-

No coolant

-

Compact and lightweight

-

Low cost application

-

Maintenance free units

-

Instant cold air in environmental chambers

-

No spark or explosion hazard

-

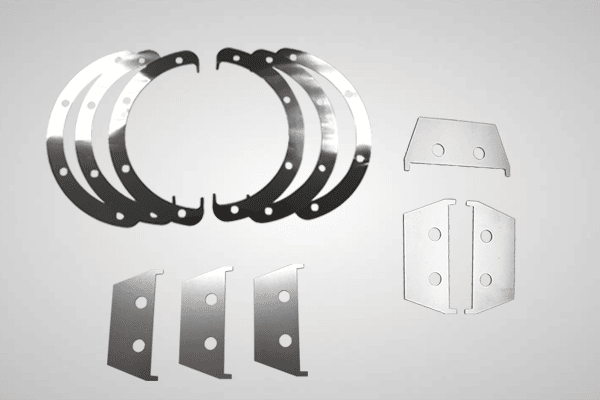

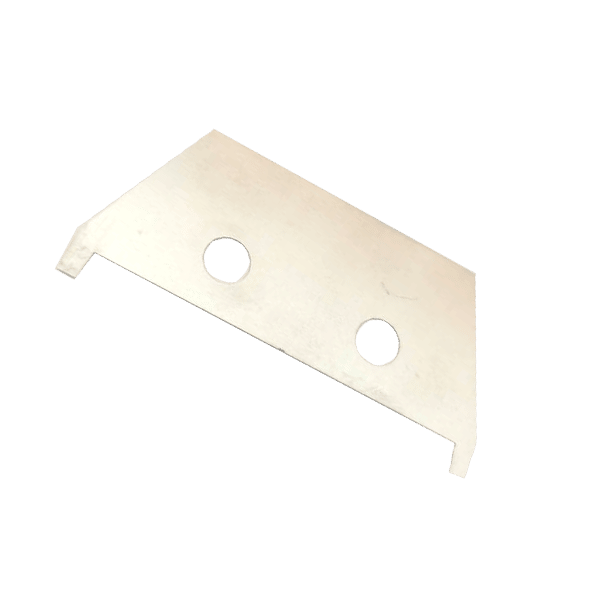

Interchangeable generators

How The Vortex Tube Work

Compressed air enters at point (A). Inside the vortex tube, the compressed air is made to spin using a “generator”. It travels in one direction along the small (hot end) tube and then back inside itself in the reverse direction creating one stream of air (B) and the second stream of air (C) in the opposite direction. The outside stream of air gets hot and exhausts at point (D). The center column of air gets cold and exists at point (E). Temperatures and capacities can vary by adjusting the hot end plug at (D) and by using different “generators”

Temperature

Adjusting the slotted valve at the hot air outlet sets the flow rate and temperature at the cold end. The more air let out at the hot end reduces the cold air flowing and the cold air temperature at the cold end. Close the valve at the hot end and you increase the cold air flow at the cold end as well as the air temperature at the cold end. The percentage of total input air to the vortex tubes that is directed to the cold end is the “cold fraction”. A cold fraction of 60% to 80% produces the optimum refrigeration. See the chart below which indicates the temperature “rise” at the hot end and temperature “drop” at the cold end of a vortex tubes at various input pressures and “cold Fraction” setting.

Most industrial applications, such as electrical control panel cooling, parts cooling, tool cooling require maximum refrigeration and utilize the Frigid-X™ 50000H series. Applications which require extreme cold temperatures such as lab sample cooling, circuit board testing, would utilize the Frigid-X™50000C series. However, mufflers are available for both the cold and hot ends if required.

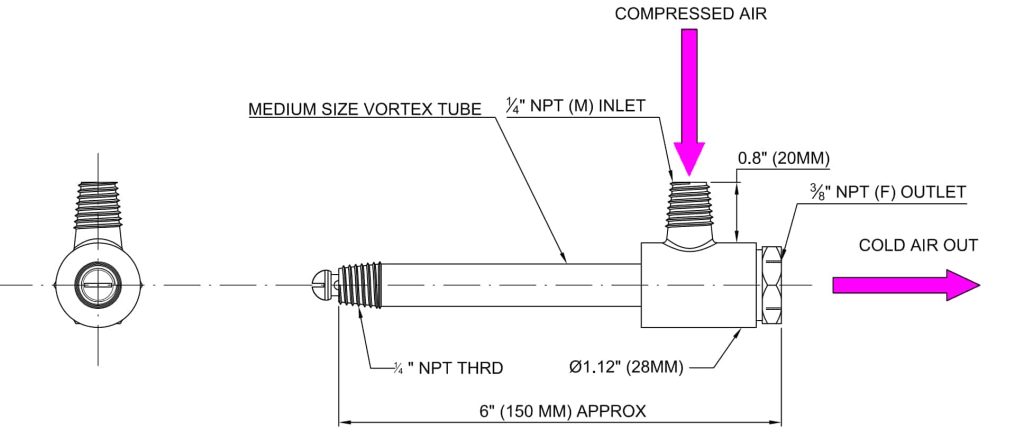

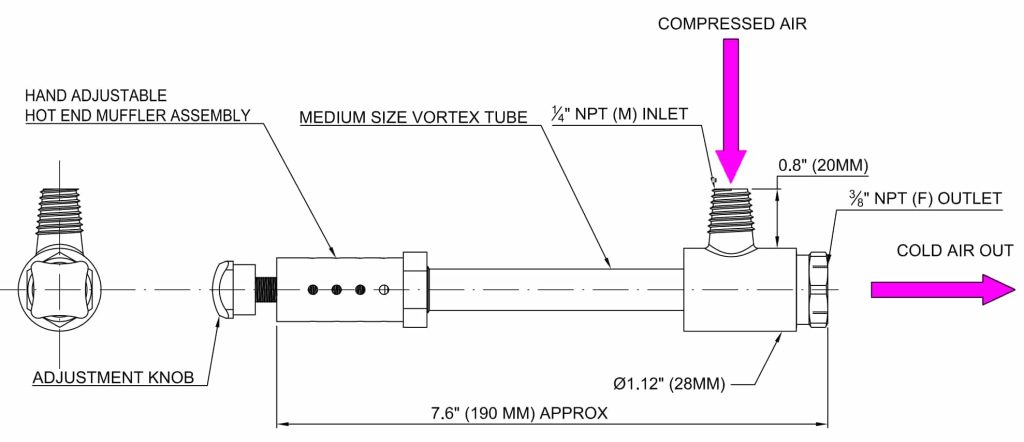

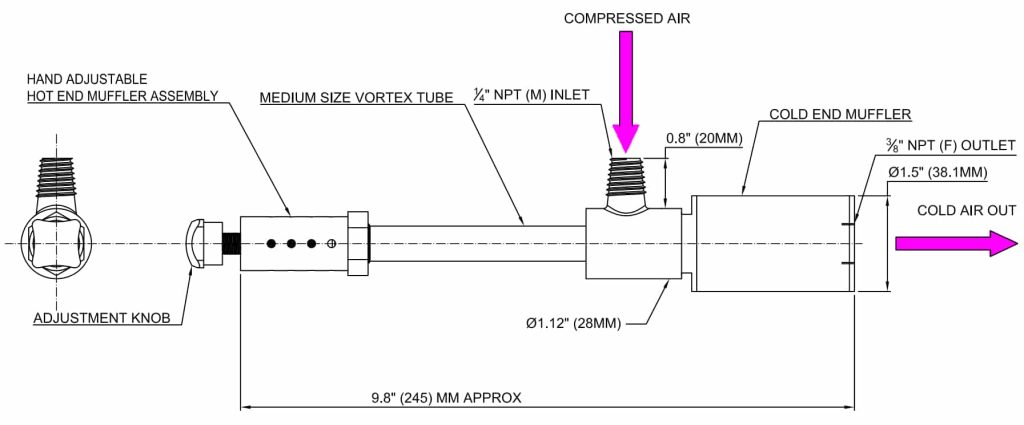

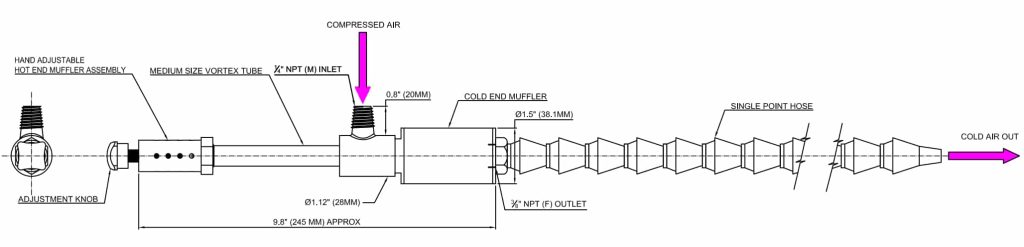

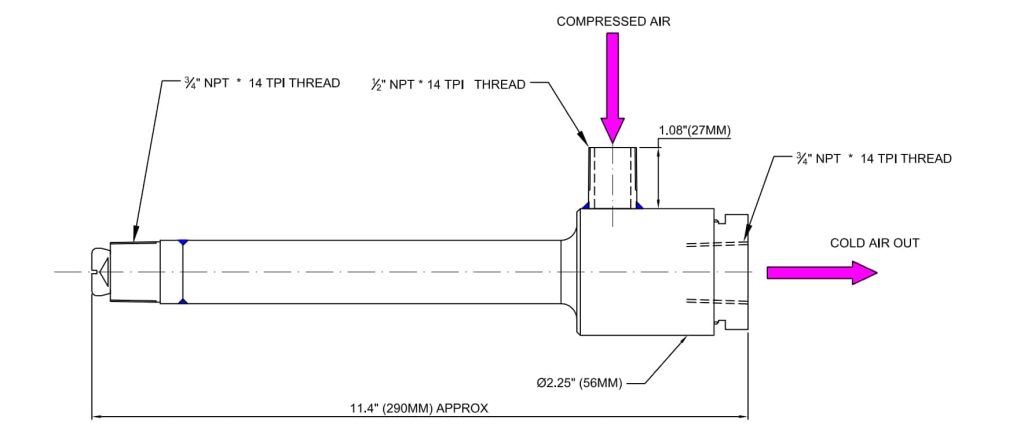

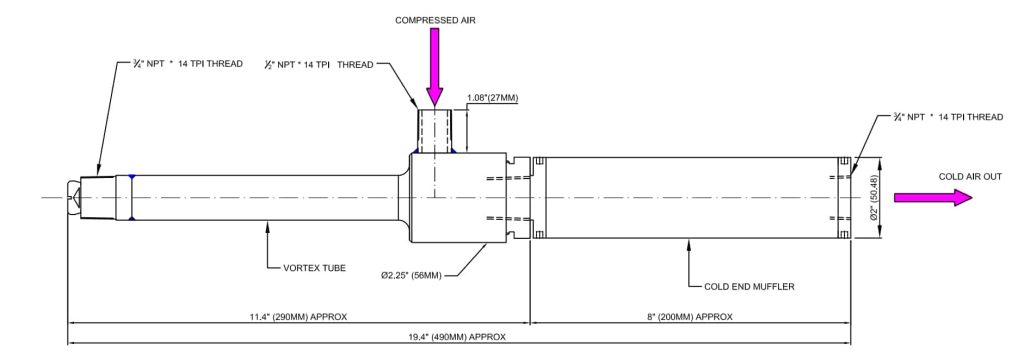

Dimensions

Small Vortex Tube with Generator

Small Vortex Tube with Generator Cold Muffler

Small Vortex Tube with Generator + Single Point Hose kit

Medium Vortex Tube with Generator

Medium Vortex Tube with Generator, Hand Adjustable Hot End Muffler Assembly

Medium Vortex Tube with Generator, Hand Adjustable Hot End Muffler Assembly + Cold Muffler

Medium Vortex Tube with Generator, Hand Adjustable Hot End Muffler Assembly + Cold Muffler + Single Point Host Kit

Medium Vortex Tube with Generator, Hand Adjustable Hot End Muffler Assembly + Single Point Host Kit

Medium Vortex Tube with Genarator + Cold End Muffler

Medium Vortex Tube with Generator + Cold End Muffler + Single Point Hose Kit

Medium Vortex Tube with Generator + Single Point Host Kit

Large Vortex Tube with Cold End Muffler

CÁC SẢN PHẨM KHÁC CÙNG NHÀ SẢN XUẤT / OTHER PRODUCTS FROM NEXFLOW |

|

|

| | |

OUR GLOBAL PARTNERS

Minato, Leap, SMH-Tech, Xeltek, Elnec, Conitec, DediProg, Phyton, Hilosystems, Flash Support Group, PEmicro ||Rigol, Tonghui, Copper Mountain, Transcom, APM || Atten, Zhuomao, Puhui, Neoden, Ren Thang, Genitec, Edry, UDK ||

CONDITTION AND USING TERMS

TULA Solution Co., Ltd - Công ty TNHH Giải pháp TULA

Headquater: No. 173 Group 15, Dong Anh District, Hanoi 10000, Vietnam

Head-Office: No. 6 Lane 23, Đình Thôn street, Mỹ Đình ward, Nam Từ Liêm Dist., Hà Nội, Vietnam

Tel.: +84-24.39655633, Hotline: +84-912612693, E-mail: info (at) tula.vn |

TIẾNG VIỆT

TIẾNG VIỆT Home

Home

Vortex Tubes: Ống Xoáy Vortex - Đầu thổi khí

Vortex Tubes: Ống Xoáy Vortex - Đầu thổi khí