Category: Main/3. Electronics Equipments & Systems for embedded electronics design and PCB assembly/3.4 SMT Line System

| | | | | ◊ Đặc điểm chính: | | Although servo motors are designed to run at high speeds, they can accurately run at extremely low speeds under very precise control, even down to 1 rpm and below with proper preparation.

|

|

|

1. Product Introduction

Although servo motors are designed to run at high speeds, they can accurately run at extremely low speeds under very precise control, even down to 1 rpm and below with proper preparation. When properly utilized, steppers are accurate and are usually a more economical solution for low-speed applications (less than 1,000 rpm). However, above 1,000 rpm, a stepper motor’s torque begins to fall off, the result of magnetic circuit time constants and core losses.

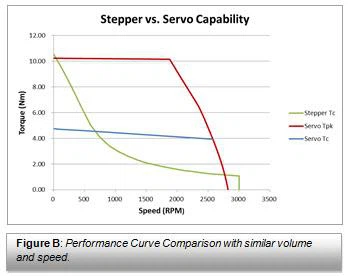

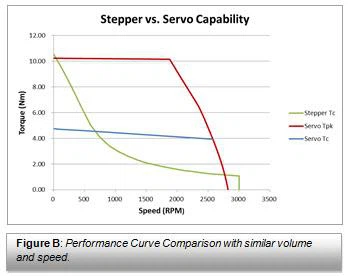

In contrast, servo motors with comparable torque do not start to fall off until around 2,000 to 4,000 rpm or more (Figure B). Direct-drive servo applications powering high-inertia loads are typically found utilizing speeds < 1000 rpm, while typical servo applications with a mechanically advantaged drive train are likely to be found using any speed within its working envelope of capability.

With a required speed range between 1,000 to 3,000 rpm, the motor type that should be used may be determined by such application requirements as horsepower, peak torque at speed, continuous (RMS) torque and repeatability.

At stall (low speeds < 50 steps/second or 15 rpm) or when holding a load with no movement, stepper motors, especially with oversized rotors, can produce more torque than servos for a given frame size (although newer servo motor designs are encroaching on this). All that torque lets steppers produce extremely accurate and stiff low-speed motion without a gearbox or other mechanical advantage.

In contrast, Direct Drive servo motors with higher pole count and high-resolution feedback are often utilized for industrial process applications requiring typical velocities of less than 1000 rpm without a mechanical advantage such as a gearhead.

When a stepper motor is at rest, it uses continuous energy and there is absolutely no movement (unless overloaded), and when not powered its detent torque capability can be used to hold position.

In contrast, a servo motor is never at rest when ON, due to the constant closed loop error correction, while only using the energy required to maintain its commanded position. The constantly varying position-loop error causes the servo’s output shaft to move back-and-forth (though it should not be noticeable), while continuously looking for minimum error. This continuous back-and-forth actuator motion is called, hunting, similar to another term, dither, a purposely induced actuator movement (e.g. valve to continuously overcome the issues of stiction). The physical displacement during hunting, typically involves only a few feedback counts, relative to the total resolution: what is unnoticeable in most applications, can be unacceptable in others (higher resolution feedback devices reduce the typical hunting delta).

Where repeatability and resolution are an issue, traditionally servo motor territory, steppers may now be considered. For steppers, the requirement is that the load must be predictable, or subject to only small external forces and disturbances, where tight coordination between axes is not required. Steppers, running open loop, can save an initial machine cost of greater than 20-30% over comparable servo solutions.

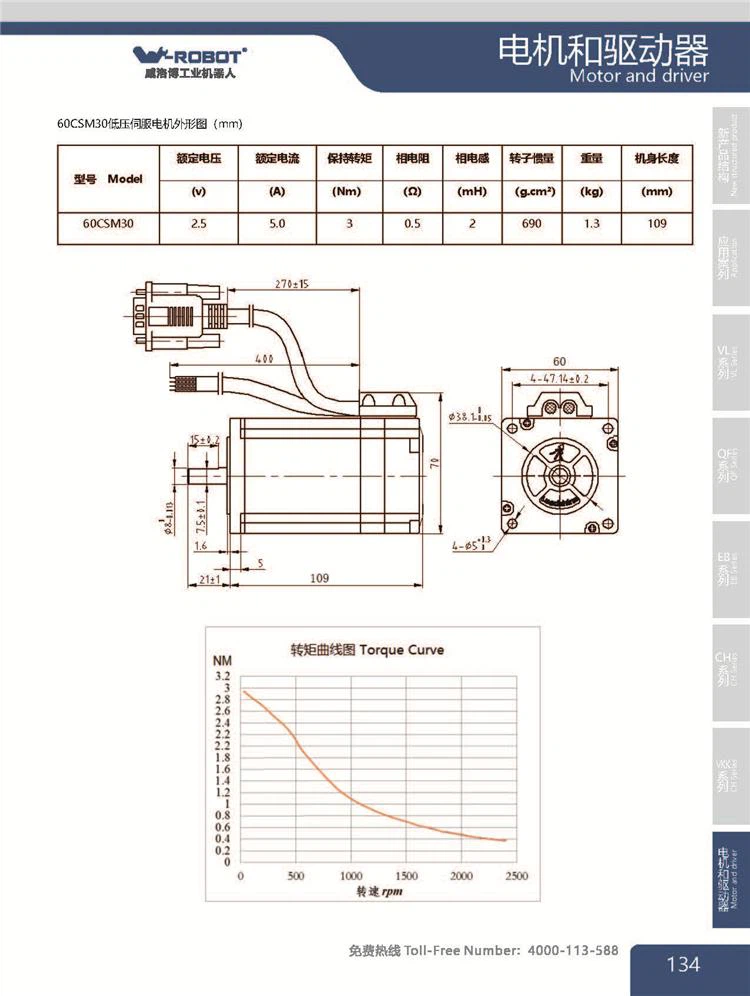

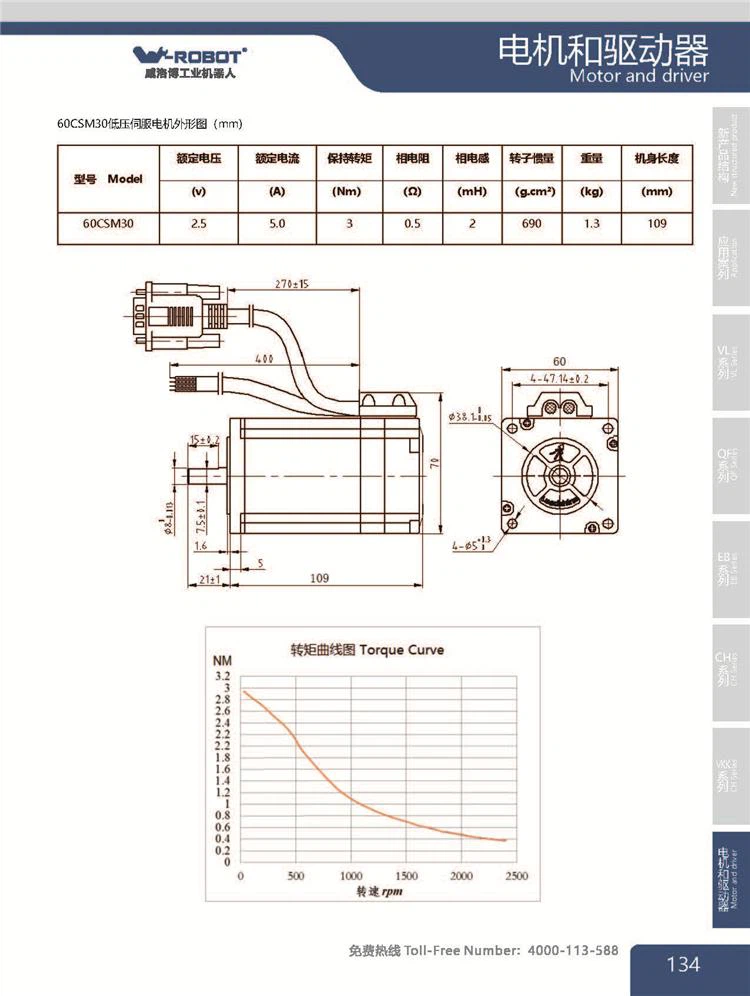

2. Product parameters.

60CSM30 stepper servo motor

CÁC SẢN PHẨM KHÁC CÙNG NHÀ SẢN XUẤT / OTHER PRODUCTS FROM WROBOT |

|

TIẾNG VIỆT

TIẾNG VIỆT Home

Home

60 Closed-loop Servomotor: Động cơ Servo

60 Closed-loop Servomotor: Động cơ Servo