| Máy nạp rom, Jig test |

| » | Máy nạp rom đa năng |

| » | Máy nạp Gang đa năng |

| » | Máy nạp rom on-board |

| » | Máy nạp chuyên biệt |

| » | Hệ thống nạp tự động |

| » | Phụ kiện đế nạp socket |

| » | Xoá Rom, kiểm tra IC |

| » | Sao chép ổ cứng, thẻ nhớ |

| » | Jig test ICT/FCT/DIP-pallet |

| Đo lường và kiểm tra |

| » | Dao động ký oscilloscope |

| » | Thiết bị viễn thông, RF |

| » | Bộ thu thập dữ liệu |

| » | Đồng hồ vạn năng số |

| » | Máy phát xung, đếm tần |

| » | Máy đo LCR, linh kiện |

| » | Bộ đổi nguồn, tải điện tử |

| » | Kit đào tạo, thực hành |

| Các công cụ sản xuất |

| » | Máy khò, mỏ hàn thiếc |

| » | Tủ sấy, tủ môi trường |

| » | Dây chuyền SMT Line |

| » | Thiết bị sản xuất PCBA |

| Thiết bị, công cụ khác |

| » | Thiết bị Automotive |

| » | Đo lực, cơ điện khác |

| » | Thiết bị quang học |

| Linh phụ kiện Điện tử |

| » | Vi điều khiển họ 8051 |

| » | Nuvoton ARM Cortex-M |

| » | Nuvoton ARM7/9 Soc |

| » | Chip phát nhạc, audio |

| » | Wireless RF IC, Tools |

| » | Vật tư hàn, rửa mạch |

| e-Shop thiết bị, vật tư |

|

|

|

Hiện tại có 0 khách và 0 thành viên đang online.

Bạn là khách. Bạn có thể đăng kí bằng cách nhấn vào đây |

OUR PARTNERS

(Products Line-Card)

|

| |

Danh mục nội dung: Chuyên mục chính/5. Vật tư, hoá chất cho sửa chữa, gia công bảng mạch PCBA/5.5. Keo đỏ SMT, keo phủ và keo đính... (Glue, adhesive, silicon, conformal coating)

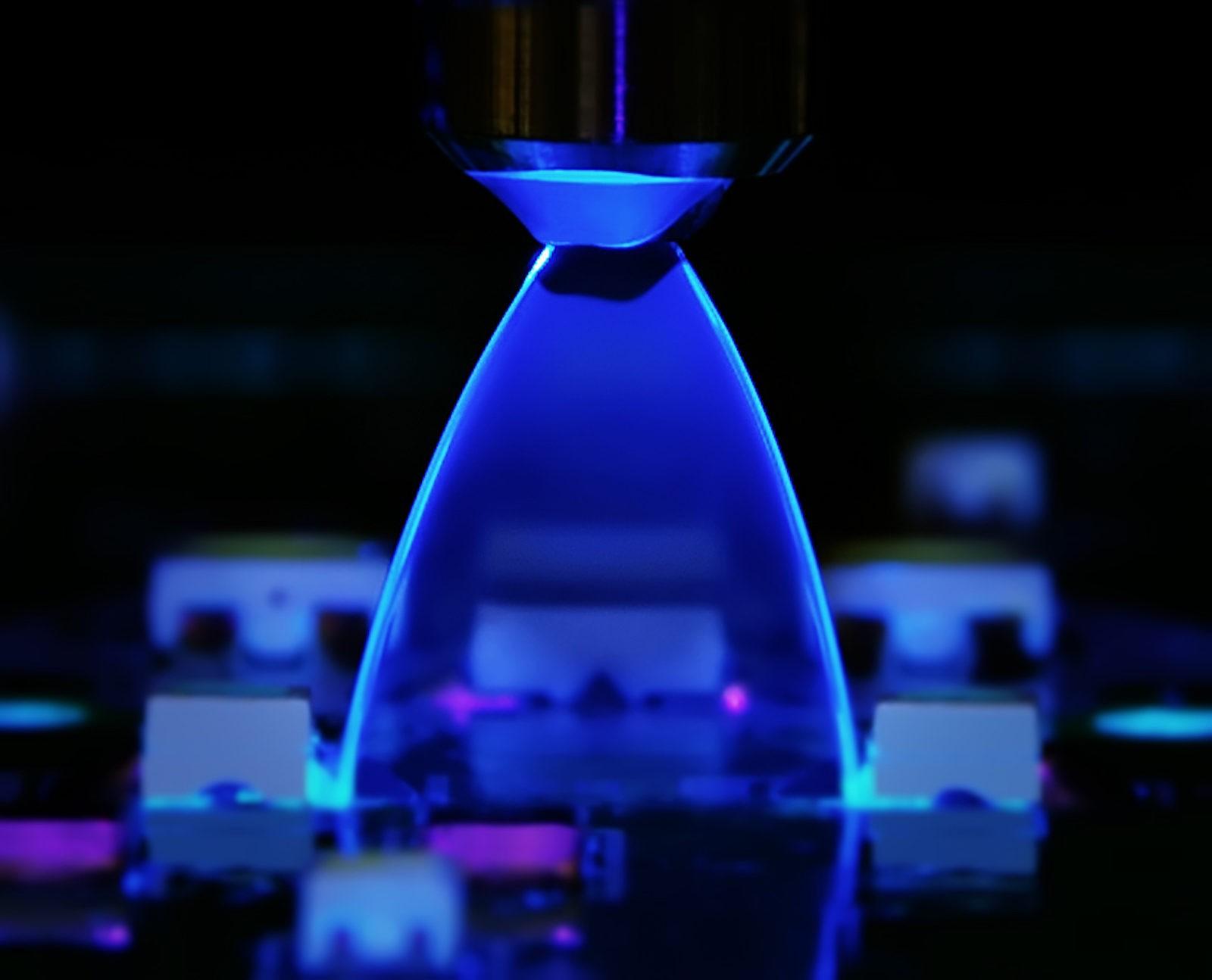

| | | | | ◊ Đặc điểm chính: | | ABchimie’s conformal coating are specially developed to ensure high protection to PCBAs from their environment. They improve and extend the working life and reliability of performance. They protect PCBs against harsh environment as salt spray, humidity, temperature, solvent and dust in general, a thin layer (25 to 50 microns). These environmental conditions can cause damage as corrosion, current leakage and failure. The complete range proposes different base of raw materials: | - Acrylic | - UV curing material (Acrylate urethane) | | - Silicone | - None VOC silicone product | | - Urethane | - 100% content | | - Aqueous urethane | |

|

|

|

An alternative to conformal coating is 3M NOVEC Electronic Grade Coatings. These are fluoropolymer coatings for challenging components in PCBA's, LED Lighting displays, MEMS and flexible circuits. They also provide anti-stiction properties for MEMS wafers. Inventec offers COMPATIBILITY of ECORELTM solder paste with our range of coatings, achieved by the compliance with the BONO test - to assure our residues -are chemically inert and reach excellent adhesion levels in No-Clean processes. - AB Chimie AVR-80-BA (Acrylic Removable Conformal Coating): AVR80 BA conformal coating is a non toxic, flexible transparent acrylic coating for the protection of electronic circuitry formulated to meet the highest resistance requirements. AVR80 BA is designed to be removed with ABchimie SND .

- Conformal Coating AB CHIMIE Acrylic thinner DVA BA: DVA BA is a non toxic solvent blend designed for use with all acrylic based conformal coatings. Especially used for AVR80 BA acrylic coating. The main uses of the thinners is to dilute the coatings for use in dip and spray coating. DVA BA R is a specific thinner which permit to reduce thinner quantity in the mix with AVR80 BA to have higher thickness on the pcb when you spray with a gun (mix is 1:1).

Quick coating selection guide

|

Properties

|

Product Name

|

Main

Features

|

|

Acrylic

|

AVR80 BA

|

No toxic, no toluene

No

toxic gases during repair Oven curing not required Quick Evaporation rate

Excellent

adhesion and dielectric properties Coating thickness 25 to 50 microns

IPC-CC-830B,

UL94V0, NF EN 61086

|

|

Acrylate Urethane UV dual cure

|

ABchimie526UV

|

UV Dual

cure coating for polymerization on shadow areas

Solvent-free

and non-flammable, no VOCs High accurate deposit and process speed Compatible

with all dispensing heads Chemical resistance

Coating thickness 30-150 microns IPC-CC-830B, UL94V0, NF

EN 61086

|

|

ABchimie526UV

LED

|

Very fast curing LED lamp version

Process

throughput comparable to UV lamp cure

No temperature applied to the substrate being coated

No extraction system required

|

|

ABchimie746E UV LED

|

Low viscosity allows to limit thickness Reduce microsplash

Soft, permanent and transparent

|

|

ABchimie42K UV LED

|

Soft resin

it can be applied in high thickness

deposit

|

|

Urethane

|

UVP100

|

Dual

cure: moisture and temperature Low VOCs

Recommended for dipping application

|

|

Silicone

|

SVP52

|

Resistant

to most solvents, lubricants and cooling fluids

High

gloss finish and high surface resistivity. Coating thickness 25 to 50 micron

|

|

SVR99

|

Good

adhesion Repairable

Excellent surface resistivity

|

WHY USE ABCHIMIE CONFORMAL COATING?ABchimie proposes a high quality of product

but also proposes ready to use product. You can ask your specific viscosity for your machinery for the same price. We bring you all technical support to help you in your process. Be present and help you is one of our

major involvement to earn your trust. HEALTH AND SAFETYABchimie is very involved in these subject, for this reason we are always looking Eco-green alternative when it’s possible. AVR80 BA is the green alternative of common acrylic conformal coating,

this version is no toxic (no labelling). The specific solvent used in this formulation permit to protect people. This reference is now very well known and used in large quantity in automotive, military and industrial application. Regarding new generation of conformal coating we propose ABchimie526 UV and ABchimie746 E UV which contains no VOC and cure with UV mercury lamp but also with a LED which permit to replace the mercury lamp but a LED lamp 395nm. APPLICATION METHODS:1. SPRAYING – Usual method. Very goods results on plane surface. 2. CANS – recommended for repairs, small and medium series. 3. SPRAY GUN – highly economic, hand spray using a spray or aerosol can. All coatings can be applied in this way. 3. SELECTIVE DEPOSIT – Different existing machineries: ASYMTEK, PVA, USI, DIMA . High performance level for mass production, reliability of deposit. All coating types can be used if the correct dispense head is selected. 4. DIPPING – To ensure presence of conformal coating even under components. it is limited to materials that do not cure quickly by moisture, light or oxidation.

HOW TO CHOOSE A CONFORMAL COATING?You will have to consider the curing method determined by the coating selected, air dry, oven dry or UV light cure. The liquid coating should thoroughly wet all surfaces and cure without leaving surface defects. Epoxies are especially sensitive to surface defects, it can also shrink while setting and may lose adhesion as a result In addition; It is very important to define well your needs: - Norms?

- PCB environment?

- Reparable?

- Electric requirement?

- How you will apply it?

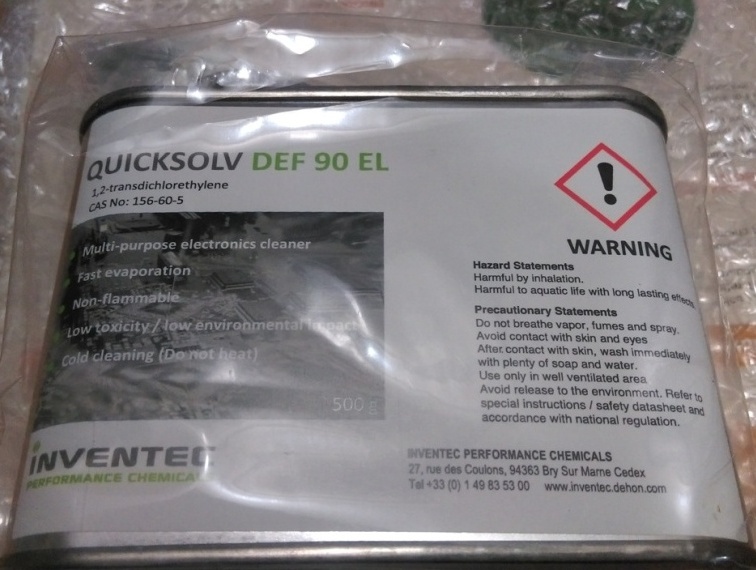

CÁC SẢN PHẨM KHÁC CÙNG NHÀ SẢN XUẤT / OTHER PRODUCTS FROM Inventec |

|

|

| | |

ĐỐI TÁC QUỐC TẾ

Minato, Leap, SMH-Tech, Xeltek, Elnec, Conitec, DediProg, Phyton, Hilosystems, Flash Support Group, PEmicro || Rigol, Tonghui, Copper Mountain, Transcom, APM || Atten, Zhuomao, Puhui, Neoden, Ren Thang, Genitec, Edry, UDK ||

|

ENGLISH

ENGLISH Trang chủ

Trang chủ

Conformal Coating: Chất phủ mạ ABchimie của Inventec

Conformal Coating: Chất phủ mạ ABchimie của Inventec